MOTOR & RELAY

Split phase motors are used in all compressors. Models

6-DF, 8-DF, and 10-DF have 2-pole, 3450 RPM motors.

The use of low starting torque motors is made possible

by unloading the compressor prior to the start, thus

reducing the required starting torque.

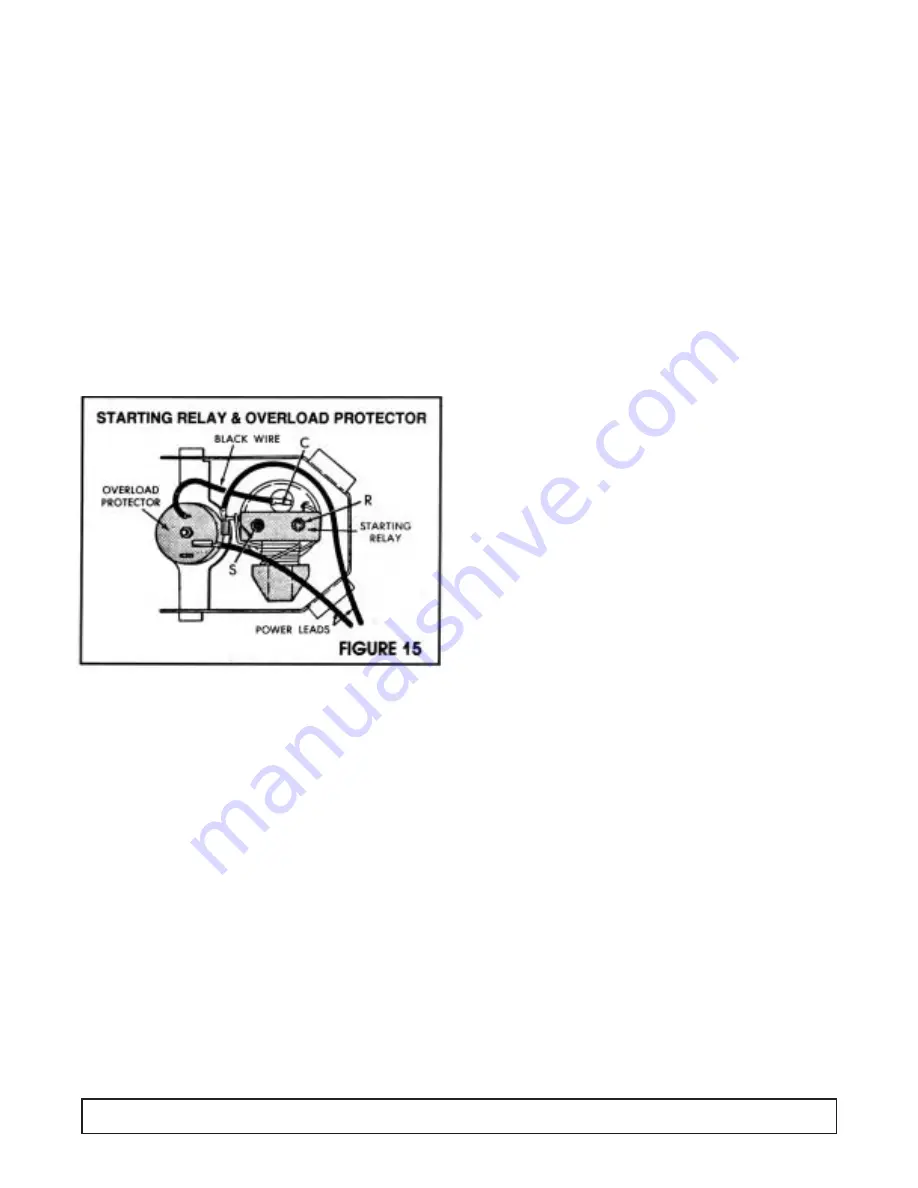

The starting relays on the “A” line compressors is the

push on type that mounts on the Start (S) and Run (R)

terminals of the compressor, as shown in Figure 15

below. The starting relay is a magnetic switch with start-

ing contacts. Its magnetic coil is in series with the run

winding of the motor. The relay coil carries the main

winding current. The relay armature holds the starting

winding contacts in open position except during the

starting period. At the moment of starting, when the

thermostat closes the electrical circuit, a surge of elec-

trical current passes through the main motor winding

and through the relay coil.

This energizes the relay coil and pulls up the relay arma-

ture, allowing the starting winding contacts to close. The

current through the start windings introduces a second

out of phase, magnetic field in the starter and starts the

value motor. As the motor speed increases, the main

winding current is reduced. At a predetermined condi-

tion, the main winding current, which is also the current

through the relay coil, drops to a value below that nec-

essary to hold in the relay armature. The armature drops

and opens the starting winding contacts and takes the

starting winding out of the circuit.

Refrigerant 404A compressors utilize a Positive

Temperature Coefficient resistor (P.T.C.) The PTC resis-

tor is connected in parallel with the run capacitor and in

series with the start winding. The PTC has a low resis-

tance when it is cold. When the motor starts the low

resistance causes a large current to flow through the

resistor. Current drawn by the resistor is out of phase

with the current drawn by the motor windings. As the

resistor draws current it begins to heat and resistance

builds to a point where it cannot flow to the start wind-

ings, thus switching current to the run windings.

In series with the motor windings is a separate bi-metal

overload protector held in place on the compressor by a

spring clip. The short wire lead on the overload protector

connects to the common (C) terminal on the compressor.

Should the current in the motor windings increase to a

dangerous point, the heat developed by passage of the

current through the bi-metal disc will cause it to deflect

and open the contacts. This act breaks the circuit to the

motor windings and stops the motor before any damage

can occur.

The overload protector provides added protection for the

compressor motor because in addition to protecting

against excessive current it also protects against exces-

sive temperature rises.

After an overload or a temperature rise has caused the

overload protector to break the circuit, the bimetal disc

cools and returns the contact to the closed position. The

time required for the overload switch to reset varies with

room temperature and compressor dome temperatures.

The overload protector is specifically designed with the

proper electrical characteristics for the compressor

motor and this ice cream cabinet application. Any

replacement must be made with the exact replacement

“NEVER SUBSTITUTE AN OVERLOAD

PROTECTOR WITH ANOTHER OF AN

UNAUTHORIZED PART NUMBER.”

The wrong protector can result in a burnt out motor. If

either the overload protector or the relay is found inop-

erative, both the relay and protector should be replaced.

When the thermostat cuts off after normal cycle or when

the service cord is pulled from the wall during a running

cycle, about eight (8) minutes time is required for

unloading (longer if it occurs during pull down), which is

the reduction of the pressure differential between the

high side and the low side of the system. During this

unloading period, the overload will trip if the service cord

is plugged into the electrical outlet.

If the compressor does not start, look for other trouble

(low line voltage—less than 100 volts at the compressor

terminals during the starting interval, inoperative relay,

inoperative compressor).

Since the relay is current operated and is designed for a

specific compressor and motor current value, the cur-

rent size relay represented by the part number is an

absolute must.

“NEVER SUBSTITUTE AN OVERLOAD

PROTECTOR WITH ANOTHER OF

AN UNAUTHORIZED PART NUMBER.”

These relays cannot be adjusted or properly repaired in

the field. If the compressor repeatedly starts and runs

for a few seconds, and then cycles on the overload pro-

tector, the starting relay contacts may be stuck closed

and the excessive current is tripping the overload.

16

GENERAL OPERATIONS