These steps are to be followed after the installation of the

gas continuous flow hot water system to ensure its safety

and performance. If the hot water system cannot be setup to

perform correctly as specified in this manual, please call the

service centre (number located in the warranty section of this

manual) for further instructions.

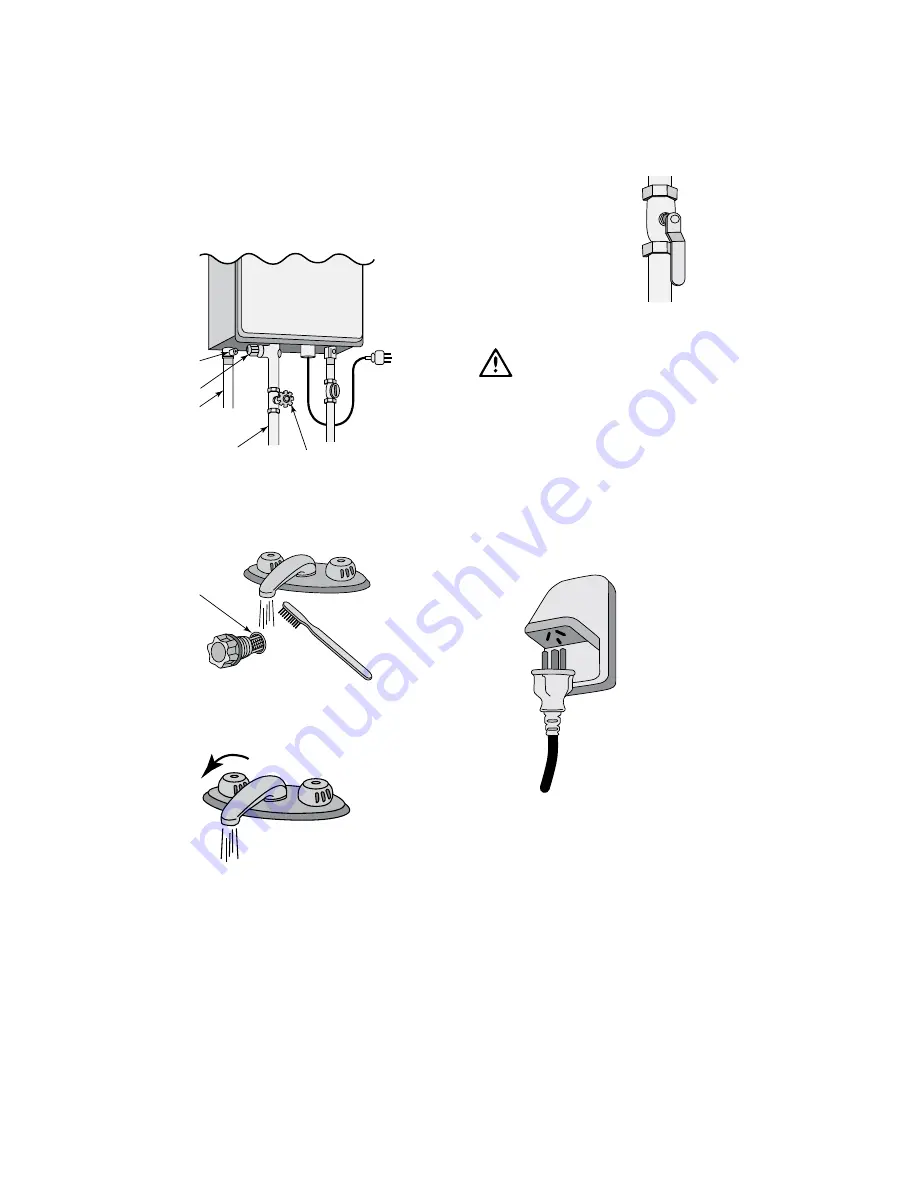

gate or ball

valve on inlet

drain plug

filter

1. Remove and clean the filter located on the cold water

inlet to the water heater (refer to page 11 of this manual).

2. Open all the hot taps and fixtures in the house.

3. Open the cold water isolation valve fully at the inlet to the

water heater

4. Check all pipe work for leaks and stop the leaks as

necessary

5. Once all the air has been forced out of the system and

water is flowing freely from every hot tap or fixture, close

all hot taps and fixtures

6. Open the gas isolation valve fully by hand at the inlet to

the water heater

7. Check the gas pipe work for leaks and stop the leaks as

necessary

caution

If there is a gas leak that cannot be stopped, do not try to

start the water heater. Do not touch any electrical switches,

use a mobile phone or any other ignition source. Close the

main gas isolating valve to the premises and walk a safe

distance away. Call the gas supplier and follow the gas

supplier’s instructions.

8. Check the inlet gas pressure (refer page 10 of this

manual).

9. Plug the power cord into the socket outlet and switch on

the electrical supply.

10. Open a hot water tap or fixture.

• If there is sufficient water flow the water heater

should start up automatically

11. Check each hot water tap or fixture to ensure that there

is sufficient flow to operate the water heater (minimum 3

litres per minute).

12. Check the temperature of the hot water at each hot tap or

fixture intended primarily for personal hygiene to ensure

the temperature is not higher than 50°C.

Commissioning instructions

16 commissioning instructions

Kelvinator Gas Continuous Flow hot water system

filter

Summary of Contents for KGC20BLA

Page 1: ...Gas Continuous Flow Hot Water System Installation Manual ...

Page 20: ...20 notes Kelvinator Gas Continuous Flow hot water system Notes ...

Page 21: ...Kelvinator Gas Continuous Flow hot water system notes 21 Notes ...

Page 22: ...22 notes Kelvinator Gas Continuous Flow hot water system Notes ...