Safety Measures

DX,LOWER -19-24FEB00-1/1

DX,PAINT -19-24JUL02-1/1

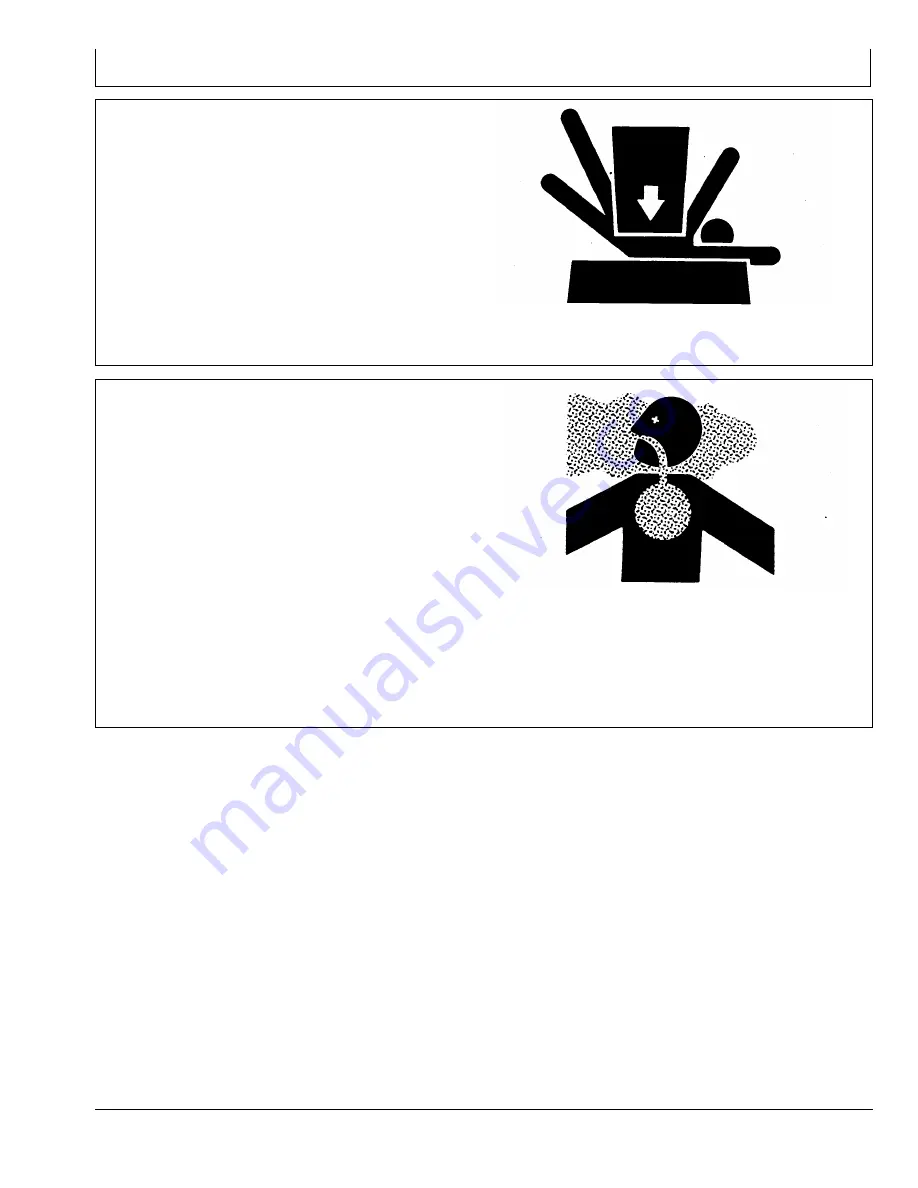

Support Machine Properly

Always lower the attachment or implement to the ground

before you work on the machine. If the work requires

that the machine or attachment be lifted, provide secure

support for them. If left in a raised position, hydraulically

supported devices can settle or leak down.

Do not support the machine on cinder blocks, hollow tiles,

or props that may crumble under continuous load. Do not

work under a machine that is supported solely by a jack.

Follow recommended procedures in this manual.

When implements or attachments are used with a

machine, always follow safety precautions listed in the

implement or attachment operator's manual.

TS229

—UN—23AUG88

Remove Paint Before Welding or Heating

Avoid potentially toxic fumes and dust.

Hazardous fumes can be generated when paint is heated

by welding, soldering, or using a torch.

Remove paint before heating:

•

Remove paint a minimum of 100 mm (4 in.) from area

to be affected by heating. If paint cannot be removed,

wear an approved respirator before heating or welding.

•

If you sand or grind paint, avoid breathing the dust.

Wear an approved respirator.

•

If you use solvent or paint stripper, remove stripper with

soap and water before welding. Remove solvent or

paint stripper containers and other flammable material

from area. Allow fumes to disperse at least 15 minutes

before welding or heating.

Do not use a chlorinated solvent in areas where welding

will take place.

TS220

—UN—15APR13

Do all work in an area that is well ventilated to carry toxic

fumes and dust away.

Dispose of paint and solvent properly.

05-7

031318

PN=13

Summary of Contents for 400F Support Wheel

Page 4: ...Contents ii 031318 PN 2...

Page 38: ...Serial Number 55 2 031318 PN 38...

Page 40: ...Index Index 2 031318 PN 2...