7 Standard Equipment

C 1200

Mounting facility

The special drive system allows three mounting options with the same basic machine:

FRONT MOUNTING – REAR MOUNTING – SIDE MOUNTING

The machine can be hitched to any tractor with cat. II 3-pt hydraulics.

Power transmission

Main PTO drive shaft with friction clutch and freewheel mechanism.

Tractors PTO speed: 1000 rpm.

Divided drive system composed of two pivoted elements: one element has two angle gears for

FRONT and REAR mounting, the other is composed of a maintenancefree powerband belt drive.

Cutting unit

New row-independent cutting system composed of a fast rotating cutting rotor. The crop is cut over the

entire working width (1.25 m) by enclosed rotary cutting blades composed of replaceable segments.

Chopping unit

Centrally adjustable flywheel (1180 rpm) fitted with 12 chopping blades with tungsten carbide coating

and special profile for extremely efficient chopping; reversible shear blade with carbide tipped edges;

built-in blade sharpener; flywheel housing fitted with replaceable wear and tear plates; rasp concave

for more efficient re-chopping, useable instead of the smooth concave.

Feeding unit

It is composed of two feed rollers with toothed bars, one springloaded precompression roller and one

smooth roller for efficient crop compression before the flywheel. The feed and precompression rollers

are driven by an oil-bath gearbox. The unit is fitted with an overload protection.

Discharge chute

Foldable discharge chute with hydraulic slewing (140

W

);

electrically adjustable discharge double flap;

one double acting control valve required on the tractor.

Chop lengths

Adjustable by changing the V-belt pulleys and by changing the number of blades.

V-belt pulley

Number of knlves

W

12

6

4

180 mm

5

10

20

210 mm

7.5

15

30

Summary of Contents for Champion C 1200

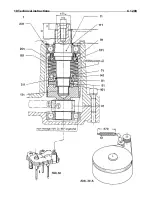

Page 13: ...10 Designation of assembly groups C 1200 ...

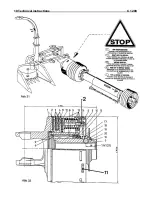

Page 15: ...12 Champion harvesting technology C 1200 ...

Page 17: ...19 Technical instructions C 1200 ...

Page 19: ...19 Technical instructions C 1200 ...

Page 29: ...30 Operating instructions C 1200 ...

Page 42: ...32 2 Blade rotor C1200 Installation position ...

Page 45: ...35 Greasing chart C 1200 ...

Page 47: ...35 Greasing chart C 1200 ...

Page 48: ...35 Greasing chart C 1200 ...

Page 51: ...38 Maintenance and inspection C 1200 ...

Page 53: ...38 Maintenance and inspection C 1200 ...