44 Troubleshooting

C 1200

Problem

Possible cause

Remedy

Excessive power demand

a) Blunt knives under the

feed mechanism

b) Defective cleaners

c) Blunt shear bar

a) Sharpen knives

b) Fit new cleaners

c) Replace shear bar

Mowing attachment not

operating smoothly or poor crop

intake

a) leaves accumulating

under the intake drum

b) Dirt in the area of the

intake drum

c) Dirt in the area of the

knives

d) Defective cleaners

a) Check several times a

day

b) Clean intake drum daily

c) Clean the area of the

knives daily

d) Renew cleaners (no.

55204) by pair to avoid

imbalance.

Vibrations

a) Damaged knives (feed

mechanism)

b) Cleaners broken away

c) Imbalance caused ba

husks, weeds and dirt

See also item 2

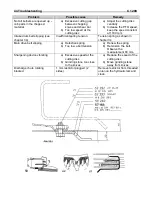

Husks accumulating in the area

of scrapers in the rear part of

the intake channel

(see

1

fig. 51).

Husks are not cleared by tines 2

or 3 (tines not close enough to

straps 4 or 5), see fig. 60 & 61

a) Bend one of the lines 2

or 3 slightly to the top

and the other to the

bottom.

b) Tines should pass as

close as possible to

strap 4 or 5

c) If necessary build up

both tine points by

welding

Maize stems are folded to the

front before being cut (long

uneven stubble)

a) Leaves or stems

accumulated around the

small divider points

b) Cleaners under knives

broken away

a) Clean divider points

b) Renew cleaners

Intake drum stops rotating

a) Overload by foreign

objects

b) Intake drum belt slipping

a) Remove foreign objects

b) Adjust tension spring as

shown in fig. 55

Stems are not cut evenly

a) Blunt or worn knives

b) Too high forward speed

a) Install new knives

b) Reduce forward speed

Maize is not chopped evenly –

too long pieces

Excessive cutting gap between

chopping knives and shear

blade

Sharpen knives, readjust cutting

disc centrally

Intake drum and cutting disc

stop rotating

a) Defective friction clutch

b) Friction clutch was not

bled prior to operation

Bleed the friction clutch (failure

to do so will void the warranty)

Defective PTO shaft

a) Insufficient maintenance

b) Friction clutch not bled

a) Service PTO as per

instructions

b) Bleed the friction clutch

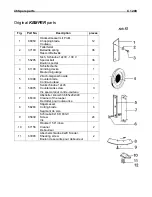

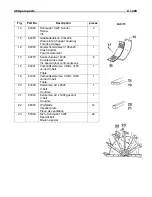

Summary of Contents for Champion C 1200

Page 13: ...10 Designation of assembly groups C 1200 ...

Page 15: ...12 Champion harvesting technology C 1200 ...

Page 17: ...19 Technical instructions C 1200 ...

Page 19: ...19 Technical instructions C 1200 ...

Page 29: ...30 Operating instructions C 1200 ...

Page 42: ...32 2 Blade rotor C1200 Installation position ...

Page 45: ...35 Greasing chart C 1200 ...

Page 47: ...35 Greasing chart C 1200 ...

Page 48: ...35 Greasing chart C 1200 ...

Page 51: ...38 Maintenance and inspection C 1200 ...

Page 53: ...38 Maintenance and inspection C 1200 ...