Service

KM00321,0000A5D -19-22APR20-1/1

KM00321,000091E -19-12APR19-1/1

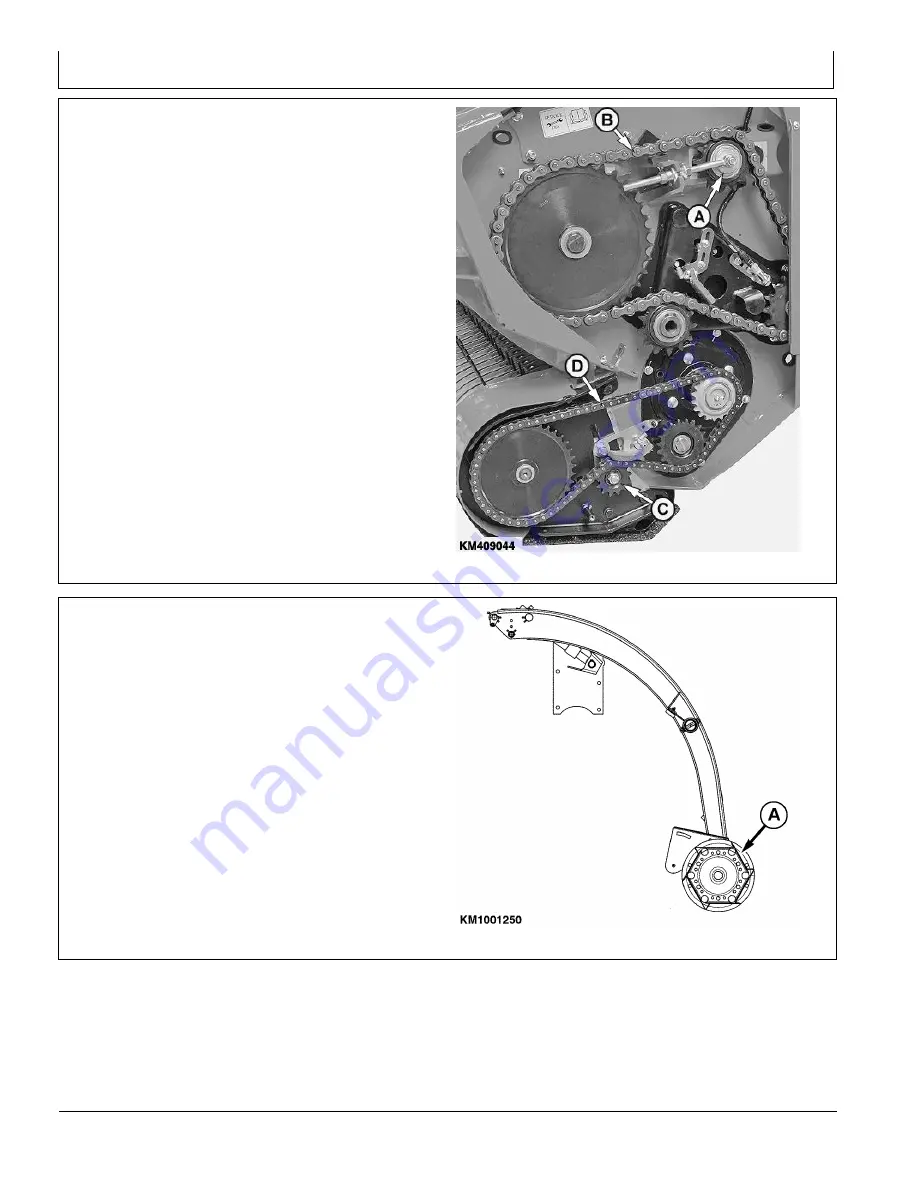

Adjust the Drive Chains

Use idler sprocket (A) to tighten chain (B) which drives

the conveyor auger.

Adjust idler sprocket (A) to get a slack of 3 to 10 mm (0.12

to 0.4 in.) on the strand opposite the drive chain idler gear.

Use idler sprocket (C) to tighten chain (D) which drives

the pickup drum.

Adjust idler sprocket (C) to get a slack of 10 to 15 mm (0.4

to 0.6 in.) on the strand opposite the drive chain idler gear.

A—Idler Sprocket

B—Conveyor Auger Drive

Chain

C—Idler Sprocket

D—Pickup Drum Drive Chain

KM409044

—UN—22APR20

Mounting Orientation of Roller

Whenever the roller (A) of the roller compression unit has

been removed, pay attention to the mounting orientation

when reinstalling roller (A).

A—Roller

KM1001250

—UN—19OCT10

65-2

010421

PN=58

Summary of Contents for Pickup N3003

Page 4: ...Introduction 010421 PN 4...

Page 6: ...Introduction 010421 PN 6...

Page 67: ...Index Index 3 010421 PN 3...

Page 68: ...Index Index 4 010421 PN 4...