KEMPER ProfiMaster Instruction Manual -

EN

Product number: 150 2464

- 65 -

rev.:

2

Technical changes and errors reserved.

Status as of: 05/2015

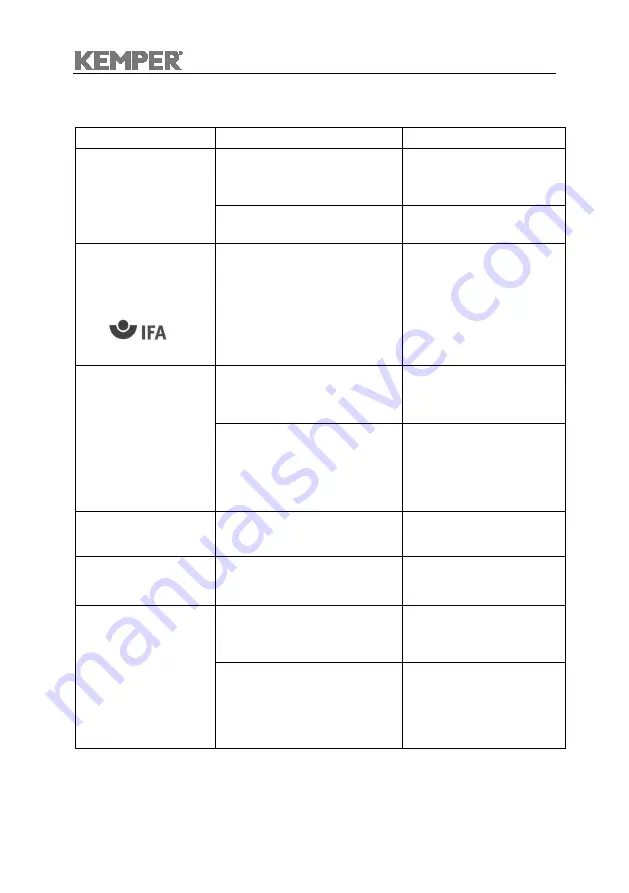

7.4 Troubleshooting

*3 Optional equipment

Failure

Possible cause

Corrective actions

All fumes cannot be

collected.

The distance of the exhaust

nozzle from the welding point

is too large.

Slide the exhaust nozzle

closer.

The clean air vent is covered.

Uncover the clean air vent.

The horn sounds,

the green signal light

on the switch is off.

Suction power is too low, the

control valve in the extraction

nozzle is closed.

Fully open the control

valve in the exhaust

nozzle.

Exhaustion power is

too low / is not

available.

Filter cartridges are clogged.

Replace filter cartridges.

Error of the sequence of

phases / missing phase

The ventilator is running in the

incorrect direction.

Changing two phases in

CEE plug by the

electrician

Dust leak on the clean

air side.

Filter cartridges are damaged. Replace filter cartridges.

Activation of the motor

protection relay.

Motor is blocked.

Call in an electrician.

The device cannot be

started.

No voltage.

Call in an electrician.

Start/Stop sensor (*3) is

connected, however, it cannot

detect current.

Welding process has not been

started yet.

Start the welding process.