EN

6.

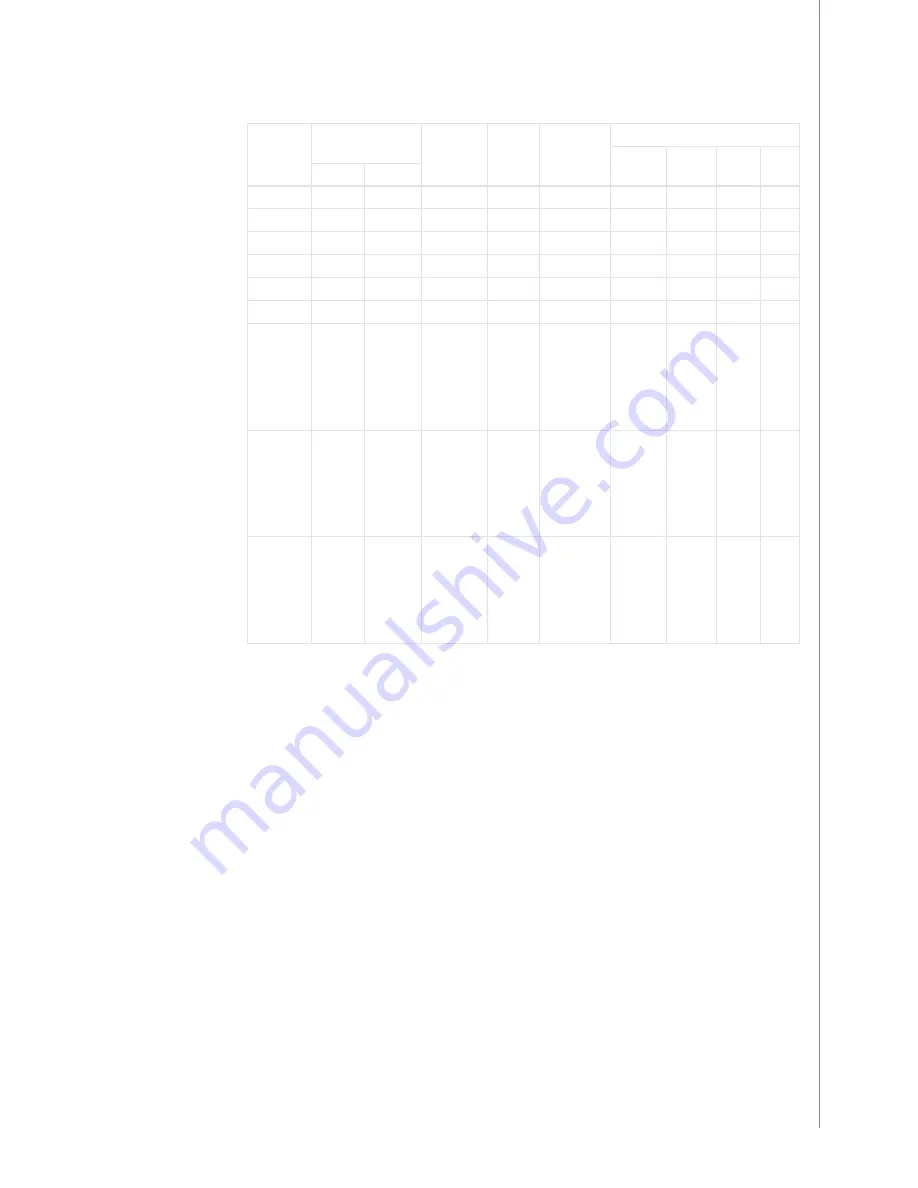

TeChniCal daTa

Loading capacity

DC-

Electrode

sizes to be

used

Voltage

class

Cooling

Connection to TIG-unit

Gas/

current

Water/

current

Water Gas

40% ED 100% ED

TTK 130

130A

-

ø 1,0 – 2,4

L

Air

R¼

-

-

-

TTK 130F

130A

-

ø 1,0 – 2,4

L

Air

R¼

-

-

-

TTK 160

160A

-

ø 1,0 – 2,4

L

Air

R¼

-

-

-

TTK 160S

160A

-

ø 1,0 – 2,4

L

Air

R¼

-

-

-

TTK 220

220A

-

ø 1,0 – 3,2

L

Air

R¼

-

-

-

TTK 220S

220A

-

ø 1,0 – 3,2

L

Air

R¼

-

-

-

TTK 300W

300A

200A

ø 1,0 – 2,4

L

Liquid

- min. 1 l/min

In inlet:

- max. 50 °C

- min. 1 bar

- max. 5 bar

-

R3/8

R3/8

R1/4

TTK 350W

350A

250A

ø 1,0 – 4,0

L

Liquid

- min. 1 l/min

In inlet:

- max. 50 °C

- min. 1 bar

- max. 5 bar

-

R3/8

R3/8

R1/4

TTK

250WS

250A

200A

ø 1,0 – 4,0

L

Liquid

- min. 1 l/min

In inlet:

- max. 50 °C

- min. 1 bar

- max. 5 bar

-

R3/8

R3/8

R1/4

Make sure that the torch being in your use is designed for max. welding current needed by

you.

The torch meets the construction and safety requirements according to norm

IEC / EN 60974-7.

9

TTK / © Kemppi O

y / 1130

Summary of Contents for 130

Page 2: ......