18

Robot Gun Cleaning Station

© Kemppi Oy 2016

1616

OPERA

TING M

ANU

AL

10.5 Attaching the cutting prism

This section describes how to fasten the cutting prism in

place.

The parts of the system are depicted in the figure below.

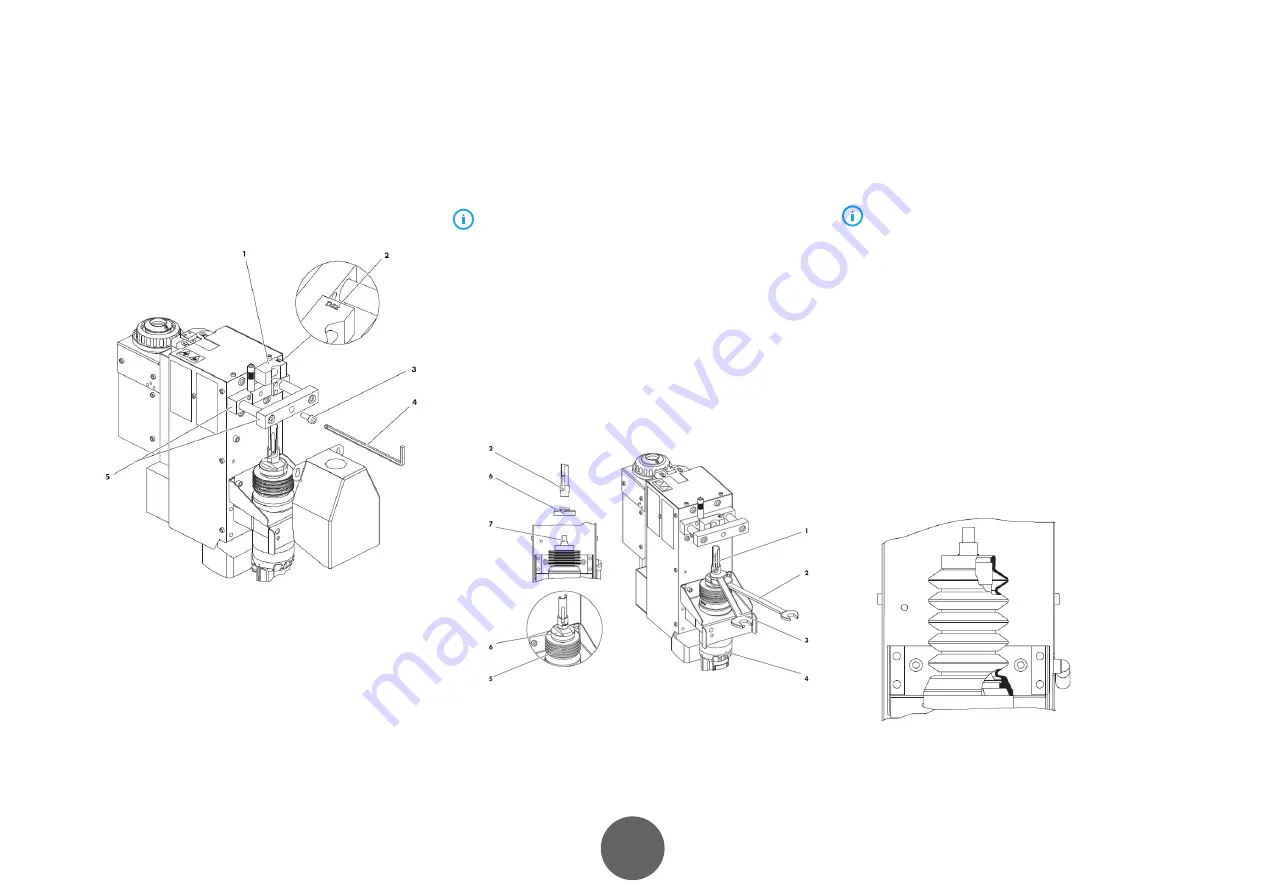

Figure 15: Installing the wire-cutting device

1. Clamping prism

2. Mark for gas nozzle Ø

3. Cylinder screw, M8×20

4. Allen key, SW 6

5. Clamping device gas nozzle

Proceed as follows:

1. Mount the clamping prism (1) in the clamping

device (5) from above.

See that a clamping prism (1) that fits the gas nozzle

diameter is mounted. You can find the diameter of the prism

marked on the prism.

2. Attach the clamping prism with the cylinder screw

(3) (tightening torque: 20 Nm).

10.6 Mounting the milling cutter

This section describes how to mount the milling cutter.

The parts of the system are depicted in the figure below.

Figure 16: Mounting the milling cutter

1. Milling cutter

2. Wrench, SW17

3. Wrench, SW21

4. Compressed-air motor

5. Bellows

6. Motor protection cap

7. Motor output shaft

Use only tools with a suitable width across flats when

replacing the milling cutter. Motor protection cap (6): SW 21;

milling cutter: SW 17.

Ensure that the bellows (5) is in the right position.

Proceed as follows:

1. Mount the motor protection cap (6).

2. Mount the milling cutter (1) on the compressed-air

motor (4).

3. Tighten the milling cutter (1) by means of the

wrench, SW17 (2) (minimum tightening torque: 20

Nm), and hold with a wrench, SW21 (3).

For a better mounting, the compressed-air motor should

be in the lower clamping and stroke position.

Figure 17: Position of the bellows