EN

4.2

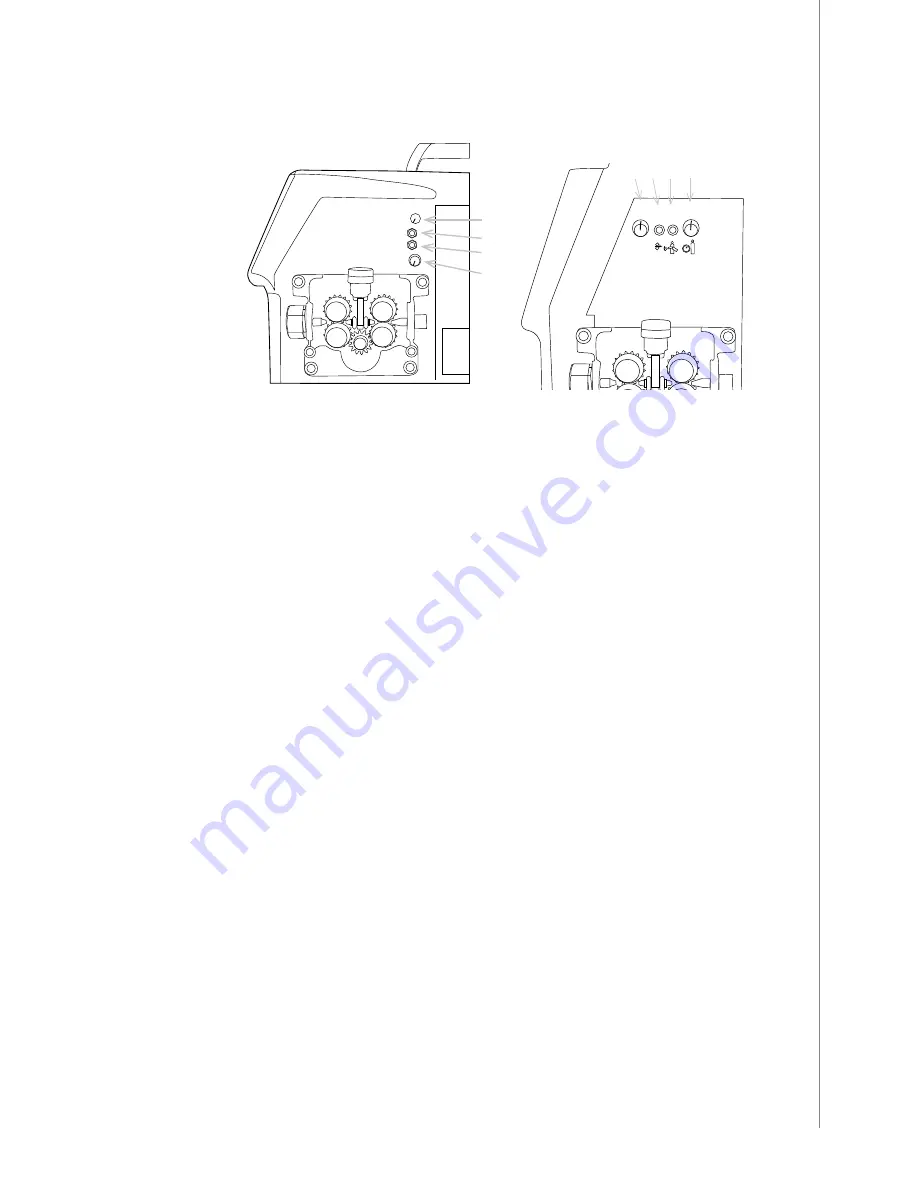

using the inside COntrOls

BURNBACK

WIRE INCH

GAS TEST

POST GAS

1

2

3

4

WIRE INCH

GAS TEST

POST GAS

BURN

BACK

WIRE

INCH

GAS

TEST

POST

GAS

1 2 3 4

ArcFeed 200

ArcFeed 300, 300p and 300rC

4.2.1 Burn back time

Burn back time control knob (1) lets you adjust the length of the post-welding current. Using

Burn back feature makes it easy to stop welding without wire sticking or burning back to the

contact tip.

4.2.2 gas test

Gas test button (2) lets you test the shielding gas and measure the gas flow.

4.2.3 wire inch

Wire inch button (3) lets you drive the welding wire without turning on the welding current.

This feature can be used for example when feeding in the new wire.

4.2.4 post gas time

Post gas time (4) control knob lets you adjust the length of the post-welding gas flow. This

feature, combined with the burn back time, provides a smooth finish of the weld.

4.3

hAnging the deviCe

The Kemppi ArcFeed 200 wire feeder should never be hanged by its handle. Use a special

hanging frame for hanging it to a welding beam or other. See 'Accessories' in Chapter

'Ordering numbers' at the end of this manual.

The Kemppi ArcFeed 300, 300P and 300RC models can be hanged by their handle by using a

special hanging device, KFH 1000. See 'Accessories' in Chapter 'Ordering numbers' at the end

of this manual.

13

A

rcF

eed 200, 300, 300P

, 300R

C / © Kemppi O

y / 1117