Service manual Mastercool 30

Version 1.0

1.11.2011

9

Kemppi Oy

4. SERVICE INSTRUCTIONS

4.1. Cooling liquid

With Mastercool 30 it is possible to use two kind of cooling liquids: Water mixed with ethanol or glycol.

Ethanol based coolant is recommended for better torch durability. It also keeps the pump clean and

smoothly running. Ethanol can be mixed with water up to 40% vol, higher volume gets flammable.

Lower % vol (no less that 15% vol) may be used if cooler is not running in subzero temperatures.

Cooler is tested with glycol based coolant and system can stay fully operational. The problem is that

glycol may corrode torch metal parts because of electricity (welding voltage in torch). Another thing is that

glycol builds up small particles in the long run and these might get the pump pressure valves stuck if

coolant is not changed frequently.

4.2. Cooler maintenance

Water cooler needs maintenance to keep it running in long term use. Water tank and pump should be

cleaned frequently. Time frame depends on the used coolant and coolers working hours. Ethanol keeps

system more clear than glycol. It is best to check in certain periods of time the coolant condition and

change if needed. Once water tank is getting dirty it should be flush with clean water.

Pump has pressure valves ant they may get dirty as well. If water circulation is slowing down and errors

are faced even with short water hoses, it is preferred to maintain the pump itself. See the following

chapters for more information.

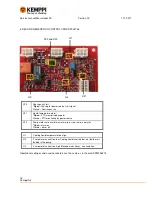

4.2.1. Detaching and fastening the pump

Detaching the pump:

•

Open the side panel

•

Disconnect the pump motor connectors

•

Detach the copper pipe

•

Detach the water hose clamp

•

Note! Additional support by finger is needed while losing the hose clamp screw

to avoid damaging the nib

•

Detach the pump from the cooler frame

Attaching the pump back to the cooler is made in the opposite rule. Note that additional support is needed

while the water hose clamp is tightened. If used dual component water hose see the next chapter to get

reliable connection.

Hose clamp

Copper pipe