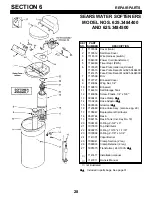

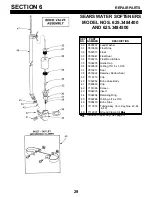

REPAIR PARTS

SECTION 6

28

SEARS WATER SOFTENERS

MODEL NOS. 625.3484400

AND 625.3484500

KEY

NO.

PART

NUMBER

DESCRIPTION

1

7137604

Cover (main)

2

7137612

Salt Hole Cover

3

7118333

Wire Harness (switch)

4

7084330

Power Cord (transformer)

5

7144960

Timer Repl. (PWA)

6

7137620

7137670

7141475

Face Plate (order req’d decal)

Face Plate Decal, Mod 625.3484400

Face Plate Decal, Mod 625.3484500

7

7137599

Rim

8

7137727

Brinewell Cover

9

7143964

Wing Nut, 1/4

″

10

7100819

Brinewell

11

7144619

Salt Storage Tank

12

7143956

Screw, Plastic, 1/4

″

x 5/8

″

13

0900431

Hose Clamp

FY

14

1103200

Hose Adaptor

FY

15

9003500

Grommet

FY

16

7123689

Brine Valve Assy. (also see pg. 29)

17

7105047

Replacement Distributor

18

0501744

Resin

19

7092155

Resin Tank (Incl. Key No. 18)

20

7096183

O-Ring, 2-3/4

″

x 3

″

21

7077870

Top Distributor

22

0900215

O-Ring, 13/16

″

x 1-1/16

″

23

7079092

O-Ring, 2-7/8

″

x 3-1/4

″

24

7141001

Vapor Barrier

25

7088041

Clamp Section (2 req.)

26

7088033

Clamp Retainer (2 req.)

27

7095373

Transformer, 24V-10VA

FY

◆

7141417

Installation manual

◆

7147811

Owners Manual

◆

not illustrated

FY

Included in parts bags. See page 31.