26

At least once a year a visual inspection should be made of the main

burner and the hot surface igniter assembly for proper flame

characteristics and ignition sequences. This can be done by removing

the Outer Door and viewing the main burner operation through the

Viewport on the Inner Door, see Figure 1. The main burner should

provide complete combustion of gas, ignite rapidly, give reasonably

quiet operation, and cause no excessive flame lifting from the burner

ports. If the proper flame characteristics are not evident (see Figure

28), make sure that the flow of combustion and ventilation air is not

blocked on the Air Intake Screen at the base of the water heater (see

Figure 29), the Lint screen on the blower assembly (see Figure 1), and

in the venting system.

You should also check for sooting. Soot is not normal and will impair

proper combustion. A visual inspection of the main burner and HSI

igniter assembly should also be done at least once a year, see

Figure 28.

Soot build-up indicates a problem that requires correction before further

use. Turn “OFF” gas to water heater and leave off until repairs are

made, because failure to correct the cause of the sooting can result in

a fire causing death, serious injury, or property damage.

FIGURE 28.

BURNER CLEANING

In the event your burner or burner air openings require cleaning, turn

the blower switch to the “OFF” position and allow the burner to cool.

Call Sears Service Center to remove and clean the burner and correct

the problem that required the burner to be cleaned.

HOUSEKEEPING

Vacuum around base of water heater for dust, dirt, and lint on a regular basis.

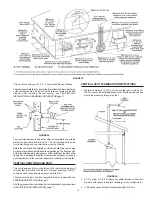

This water heater unit is supplied with a plastic Air Intake Screen that will

filter and prevent lint build-up on the bottom of the flame arrestor of this

heater. To prevent the lint build-up on the arrestor, the lint screen must be

installed on the Base Pan with the “arrows” pointing upwards as shown

in Figure 29. If the Air Intake Screen is missing from this heater, please

contact Sears Service Center for a replacement part.

FIGURE 29.

AT LEAST ONCE EVERY SIX MONTHS A VISUAL INSPECTION

SHOULD BE MADE OF THE AIR INTAKE SCREENS ON THE BASE

OF THE WATER HEATER AND THE BLOWER ASSEMBLY. CLEAN

IF LINT ACCUMULATIONS ARE NOTICED.

INSTALLED IN SUITABLE AREA: To insure sufficient ventilation and

combustion air supply, proper clearances from the water heater must

be maintained. See “Facts to Consider About the Location” section.

Combustible materials such as clothing, cleaning materials, or flammable

liquids, etc. must not be placed against or adjacent to the water heater

which can cause a fire.

ANODE ROD INSPECTION

The anode rod is used to protect the tank from corrosion. Most hot

water tanks are equipped with an anode rod. The submerged rod

sacrifices itself to protect the tank. Instead of corroding the tank,

water ions attack and eat away the anode rod. This does not affect

the water’s taste or color. The rod must be maintained to keep the tank

in operating condition.

Anode deterioration depends on water conductivity, not necessarily

water condition. A corroded or pitted anode rod indicates high water

conductivity and should be checked and/or replaced more often than

an anode rod that appears to be intact. Replacement of a depleted

anode rod can extend the life of your water heater. Inspection should

be conducted by a qualified technician, and at a minimum should be

checked annually after the warranty period.

TEMPERATURE-PRESSURE

RELIEF VALVE OPERATION

The temperature-pressure relief valve must be manually operated at

least once a year.

Summary of Contents for ECONOMIZER 6 153.332070

Page 3: ...3 SAFETY PRECAUTIONS ...