17

The appliance and its gas connection must be leak tested before

placing the appliance in operation.

The appliance and its individual shutoff valve shall be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/2 pound per square inch (3.5kPa). It shall be isolated from

the gas supply piping system by closing its individual manual

shutoff valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 pound per

square inch (3.5kPa).

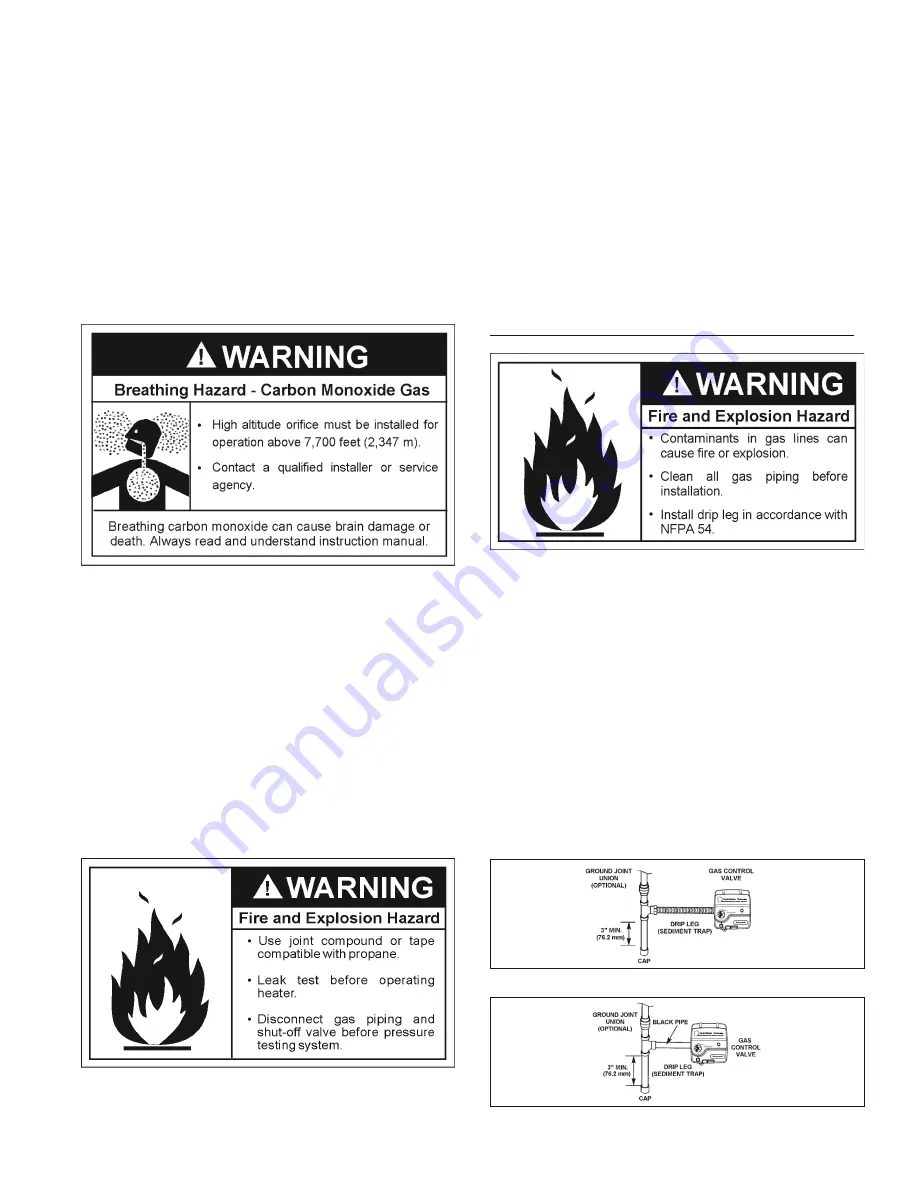

Connecting the gas piping to the gas control valve of the water

heater can be accomplished by either of the two methods shown

in Figures 19 and 20.

There must be:

• A readily accessible manual shut off valve in the gas supply

line serving the water heater, and

• A drip leg (sediment trap) ahead of the gas control valve to

help prevent dirt and foreign materials from entering the gas

control valve.

• A fl exible gas connector or a ground joint union between

the shut off valve and control valve to permit servicing of the

unit.

Be sure to check all the gas piping for leaks before lighting the

water heater. Use a soapy water solution, not a match or open

fl ame. Rinse off soapy solution and wipe dry.

The minimum inlet gas pressure shown on the rating plate is that

which will permit fi ring at the rated input.

Water heaters covered in this manual have been tested and

approved for installation at elevations up to 7,700 feet (2,347 m)

above sea level. For installation above 7,700 feet (2,347m),

the water heater’s Btu input should be reduced at the rate of

4 percent for each 1,000 feet (305 m) above sea level which

requires replacement of the burner orifi ce in accordance with the

National Fuel Gas Code ANSI Z223.1/NFPA 54. Contact your

local gas supplier for further information.

Failure to replace the standard orifi ce with the proper high

altitude orifi ce when installed at elevations above 7,700 feet

(2,347m) could result in improper and ineffi cient operation of

the appliance, producing carbon monoxide gas in excess of the

safe limits. This could result in serious injury or death. Contact

your local gas supplier for any specifi c changes that may be

required in your area.

Use pipe joint compound or tefl on tape marked as being

resistant to the action of petroleum (Propane [L.P.]) gases.

Sediment Traps

Contaminants in the gas lines may cause improper operation

of the gas control valve that may result in fi re or explosion.

Before attaching the gas line be sure that all gas pipe is clean

on the inside. To trap any dirt or foreign material in the gas

supply line, a drip leg (sometimes called a sediment trap) must

be incorporated in the piping. The drip leg must be readily

accessible. Install in accordance with the

Gas Piping

section.

Refer to the current edition of th

e National Fuel Gas Code,

ANSI Z223.1/NFPA 54.

A sediment trap shall be installed as close to the inlet of the water

heater as practical at the time of water heater installation. The

sediment trap shall be either a tee fi tting with a capped nipple

in the bottom outlet or other device recognized as an effective

sediment trap. If a tee fi tting is used, it shall be installed in

conformance with one of the methods of installation, shown in

Figures 19 and 20.

FIGURE 19. GAS PIPING WITH FLEXIBLE CONNECTOR.

FIGURE 20. GAS PIPING WITH ALL BLACK IRON PIPE TO

GAS CONTROL.

Summary of Contents for HydroSense 153.33443

Page 3: ...3 SAFETY PRECAUTIONS ...

Page 18: ...18 OPERATING INSTRUCTIONS ...

Page 27: ...27 FIGURE 28 GAS VALVE BACKPLATE GAS VALVE NIPPLE ...

Page 31: ...31 NOTES ...