4

TABLE OF CONTENTS

SAFE INSTALLATION, USE AND SERVICE ...................................................................................................................................... 2

GENERAL SAFETY ............................................................................................................................................................................ 3

TABLE OF CONTENTS ...................................................................................................................................................................... 4

INTRODUCTION ................................................................................................................................................................................ 5

PRODUCT SPECIFICATIONS ........................................................................................................................................................... 5

MATERIALS AND BASIC TOOLS NEEDED ...................................................................................................................................... 6

Materials Needed ......................................................................................................................................................................... 6

Basic Tools ................................................................................................................................................................................... 6

Additional Tools Needed When Sweat Soldering ........................................................................................................................ 6

INSTALLATION INSTRUCTIONS .................................................................................................................................................. 7-16

Removing the Old Water Heater .............................................................................................................................................. 7,8

Facts to Consider About the Location ......................................................................................................................................... 8

Insulation Blankets ....................................................................................................................................................................... 8

Facts to Consider About the Convertible Lower Element ......................................................................................................... 8,9

Water Piping ........................................................................................................................................................................... 9,10

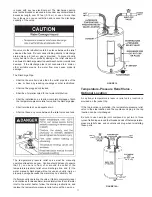

T & P Valve and Pipe Insulation ................................................................................................................................................ 10

Temperature-Pressure Relief Valve ...................................................................................................................................... 10,11

Temperature-Pressure Relief Valve- Optional Location ....................................................................................................... 11,12

Filling the Water Heater ............................................................................................................................................................. 12

Converting the Lower Element ............................................................................................................................................. 12-14

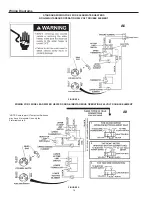

Wiring .................................................................................................................................................................................... 14,15

Wiring Diagrams ........................................................................................................................................................................ 16

SERVICE AND ADJUSTMENT .................................................................................................................................................... 17-22

Temperature Regulation ............................................................................................................................................................. 17

Thermostat ................................................................................................................................................................................. 17

Temperature Settings ................................................................................................................................................................. 17

Upper and Lower Thermostat Adjustments .......................................................................................................................... 17,18

Anode Rod Inspection ................................................................................................................................................................ 18

Temperature-Pressure Relief Valve Operation .......................................................................................................................... 18

Draining ................................................................................................................................................................................. 18,19

Thermostat Removal/Replacement ........................................................................................................................................... 19

Element Cleaning/Replacement ........................................................................................................................................... 19-22

Drain Valve Washer Replacement ............................................................................................................................................. 22

Service ....................................................................................................................................................................................... 22

TROUBLESHOOTING GUIDE .................................................................................................................................................... 23-26

Start Up Conditions .................................................................................................................................................................. 23

Thermal Expansion ............................................................................................................................................................ 23

Strange Sounds ................................................................................................................................................................. 23

Operational Conditions ......................................................................................................................................................... 23-25

Smelly Water ................................................................................................................................................................. 23,24

“Air” in Hot Water Faucets ................................................................................................................................................. 24

Rumbling Noise .................................................................................................................................................................. 24

High Temperature Shut Off System .................................................................................................................................... 24

Not Enough or No Hot Water ........................................................................................................................................ 24,25

Water Is Too Hot ................................................................................................................................................................. 25

Leakage Checkpoints ............................................................................................................................................................ 25,26

REPAIR PARTS LIST ....................................................................................................................................................................... 27

WARRANTY ..................................................................................................................................................................................... 28

Summary of Contents for POWER MISER 153.326162

Page 3: ...3 GENERALSAFETY ...