31

I)

Storage of Grinding Wheel

The wheels should be kept in special racks in a dry place and must be protected from

knocks and jolts, especially when they are being transported.

As a rule, they should be stood on edge, but thin wheels and wheels with a sharp edge must

be laid flat on an even surface.

Grinding wheels must not be allowed to come into contact with oil or grease. An oil

soaked wheel loses its bite and its application is very limited.

J)

Selection of Suitable Grinding Wheels

Grinding wheel markings: For instance WA 46K8V

WA: Kind of abrasive

46: Grain size

K: Grade

8: Structure

V: Bond type

(a).Kinds of abrasive

A: For common steel grinding

WA: For higher hardness material grinding, such as heat-treated steel, alloy steel, etc.

H: Suitable for higher hardness material, particularly high speed steel

C: For cast iron and non-ferrous grinding

GC: For super hard grinding such as tungsten carbide steel

(b).Grain size

Coarse:10,12,14,16,20,24

Medium:30,36,46,54,60

Fine:70,80,90,100,120,150,180

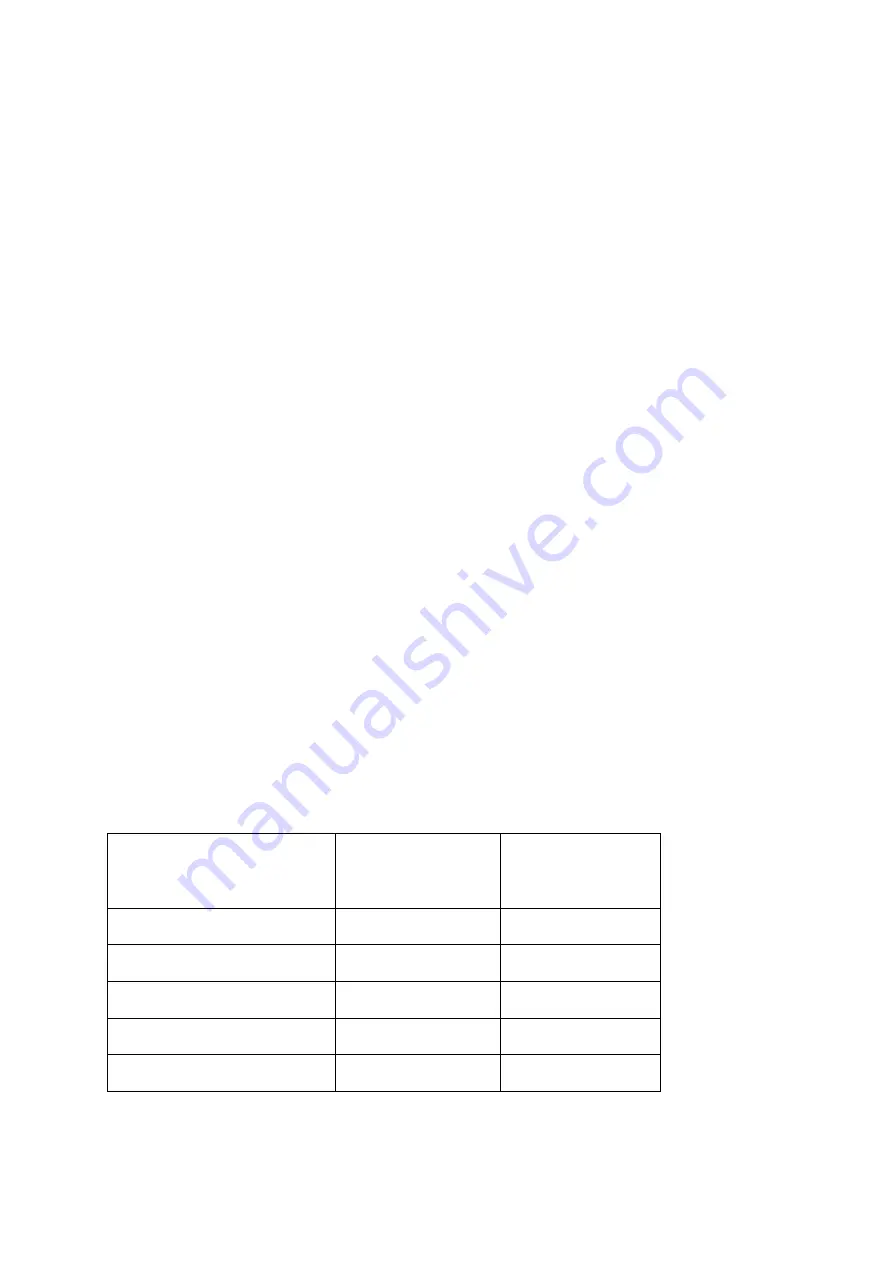

Grade

Grinding

condition

Coarse

Fine

Feed increment

much

little

Surface roughness

coarse

fine

Works hardness

soft

hard

Surface contacted

wide

narrow

Dia. of the wheel

big

small

Property

of

Kent

Industrial

USA

Please

Do

Not

Reproduce