R AD AR

91

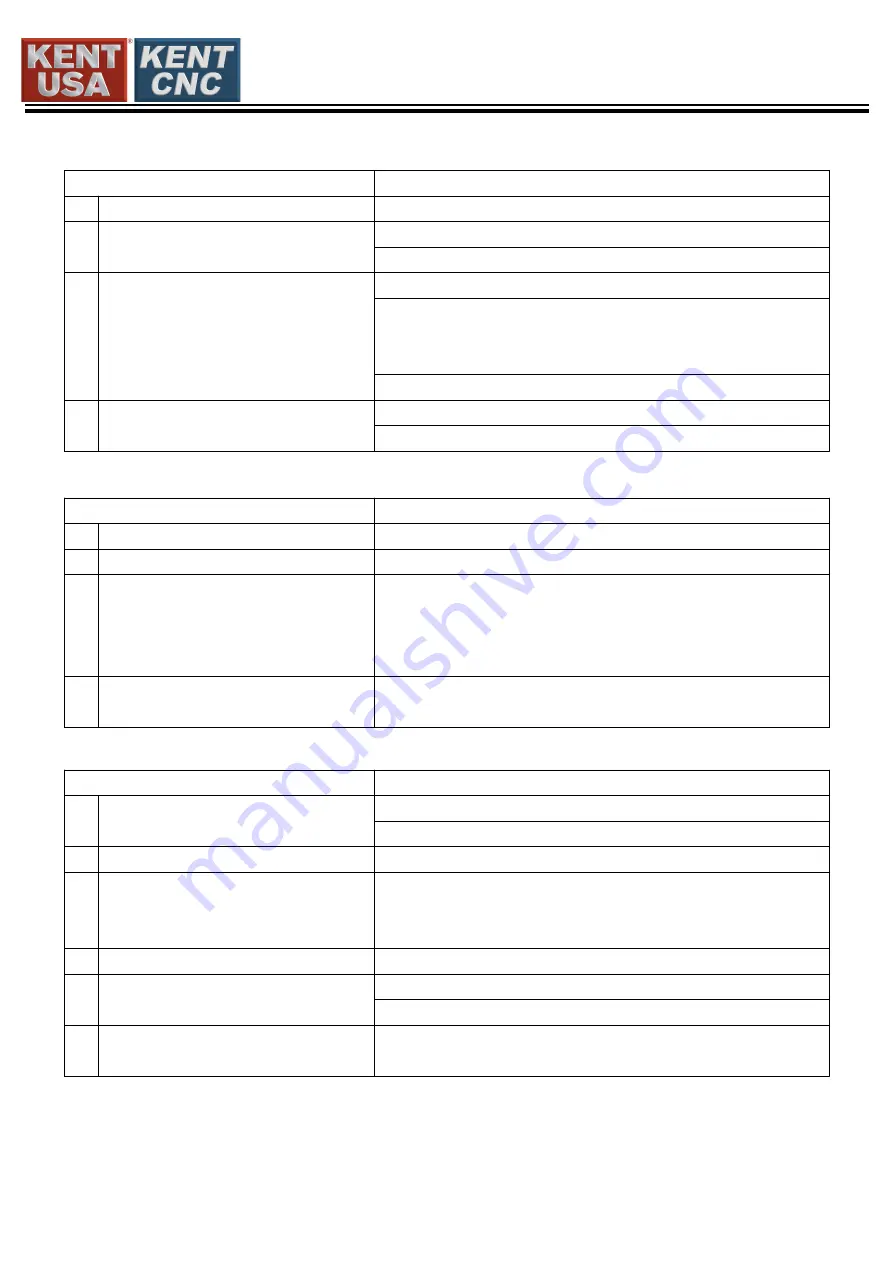

Reason

Countermeasure

Reason

Countermeasure

Reason

Countermeasure

Check.

Check, repair it if necessary.

Check screws loosing, or foreign inside the

Retighten the screws, remove foreign objects,

Inappropriate hydraulic oil.

Hydraulic oil contaminated.

Abnormal pressure.

Test run period, the hydraulic oil

pressure inadequate.

Inappropriate hydraulic oil.

Hydraulic oil contaminated.

Abnormal pressure.

Operating pressure or flow rate

Hydraulic oil viscosity is too high.

Decreased performance

or lack of hydraulic oil cooler.

Hydraulic oil shortage.

Inappropriate pipelining.

Inadequate cooling

higher than the set value.

Replacing the appropriate hydraulic oil.

Remove foreign, check the filter is blocked or not and

Check valves and accumulators.

Check the diameter of two connected pipe,

Use the similar diameter of pipes to connect,

Exclude pipe bending as possible as you can

Check the hydraulic circuit.

Open and check.

Replace it if necessary.

clean it, replaced with new hydraulic oil.

motor or pump.

and re-lock.

Check the circuit of control unit.

Test run period, the hydraulic oil

pressure inadequate.

Install the cooling machine.

If necessary, to reduce the pressure or flow.

Replacing the appropriate hydraulic oil.

Clean the components of cooling machine.

Install extra cooling machine, or if necessary replace

Check, if necessary, add hydraulic oil.

Check the flow and pipe size.

Check with the flow.

Check the hydraulic transmission is over heating or

large power cooler.

the cooling circuit is malfunction.

Pump damage or wear

c.

Motor over heated or burned

d.

Hydraulic oil over heating

e.

1.

1.

1.

2.

2.

2.

3.

3.

3.

4.

4.

4.

5.

6.

7.

Troubleshooting

7.

Troubleshooting

7.

Troubleshooting

7.

Troubleshooting

7.

Troubleshooting

7.

Troubleshooting

7.

Troubleshooting

7.

Troubleshooting

7.

Troubleshooting

7.

Troubleshooting

Property

of

Kent

Industrial

USA

Do

Not

Reproduce