39

IMPORTANT NOTE

This appliance is supplied for use on NATURAL GAS or LPG (check the gas regulation

label attached on the appliance).

•

Appliances supplied for use on NATURAL GAS: they are adjusted for this gas only

and cannot be used on any other gas (LPG) without modification. The appliances are

manufactured for conversion to LPG.

•

Appliances supplied for use on LPG: they are adjusted for this gas only and cannot

be used on any other gas (NATURAL GAS) without modification. The appliances are

manufactured for conversion to NATURAL GAS.

If the NATURAL GAS/LPG conversion kit is not supplied with the appliance this kit can be

purchased by contacting the After-Sales Service.

INSTALLATION & SERVICE REGULATIONS (UNITED KINGDOM)

It is a legal requirement that all gas appliances are Installed & Serviced by a competent

person in accordance with the current editions of the following Standards & Regulations or

those regulations appropriate to the geographical region in which they are to be installed:

•

Gas Safety (Installation & Use) Regulations

•

Building Regulations

•

British Standards

•

Regulations for Electrical Installation

Installation and service of any gas product must be made by a suitably qualified and

registered person competent on the type of product being installed or serviced and holding

a valid certificate of competence for the work being carried out. Currently the proof of

competence is the Accredited Certification Scheme (ACS) or S/NVQ that has been aligned

to the ACS.

It is also a requirement that all businesses or self employed installers are members of a

class of person approved by the Health and Safety Executive.

Failure to install the appliance correctly could invalidate any manufacturers warranty and

lead to prosecution under the above quoted regulation.

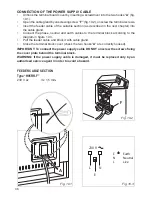

9 - GAS INSTALLATION