38

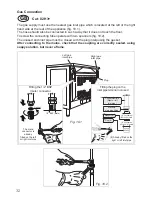

RIGHT OVEN:

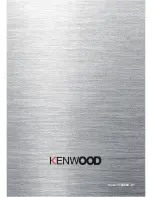

REPLACEMENT OF THE INJECTOR

OF THE OVEN BURNER

Lift and remove the lower panel inside

•

the oven.

Remove the 2 screws securing the

•

burner (fig. 10.13).

Withdraw the burner as shown in fi

-

•

gure 10.14 and rest it inside the oven.

Take care not to damage the wire to

the ignition electrode and the safety

valve probe.

Using a 7 mm box spanner, unscrew

•

the injector (indicated by the arrow in

fig. 10.14) and replace it by the proper

one according to the kind of gas. Then

replace the burner repeating the abo-

ve steps in reverse order.

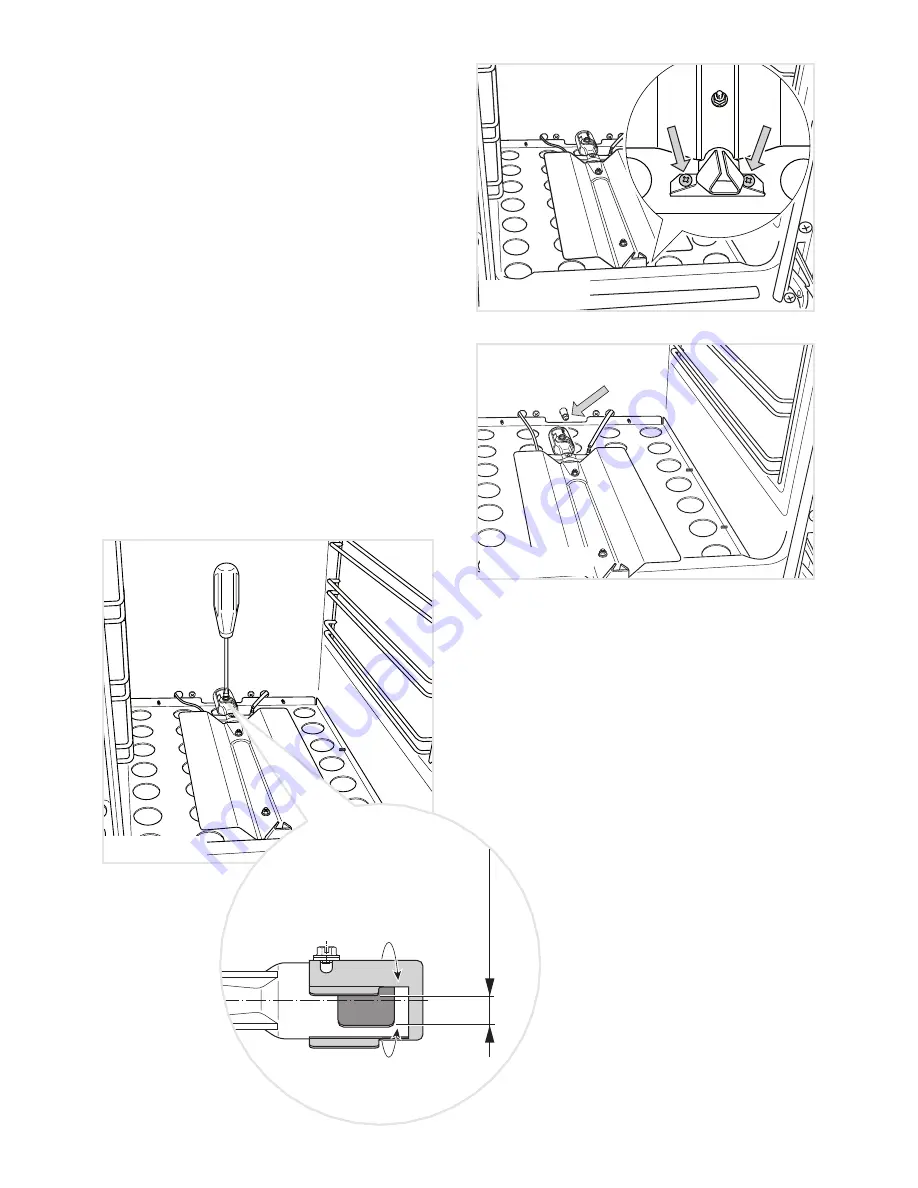

Ring opening

Fig. 10.15

Fig. 10.14

Fig. 10.13

RIGHT OVEN:

REGULATION OF AIR SUPPLY TO

THE OVEN BURNER

Using a screwdriver, slacken the screw

securing the air flow regulation collar (fig.

10.15) and rotate the collar clockwise or

anti-clockwise to increase or reduce the air

aperture in accordance with gas type and

the indications in the “TABLE FOR THE

CHOICE OF THE INJECTORS”.

Light the burner and check the

flame.