25

Fig. 8.9

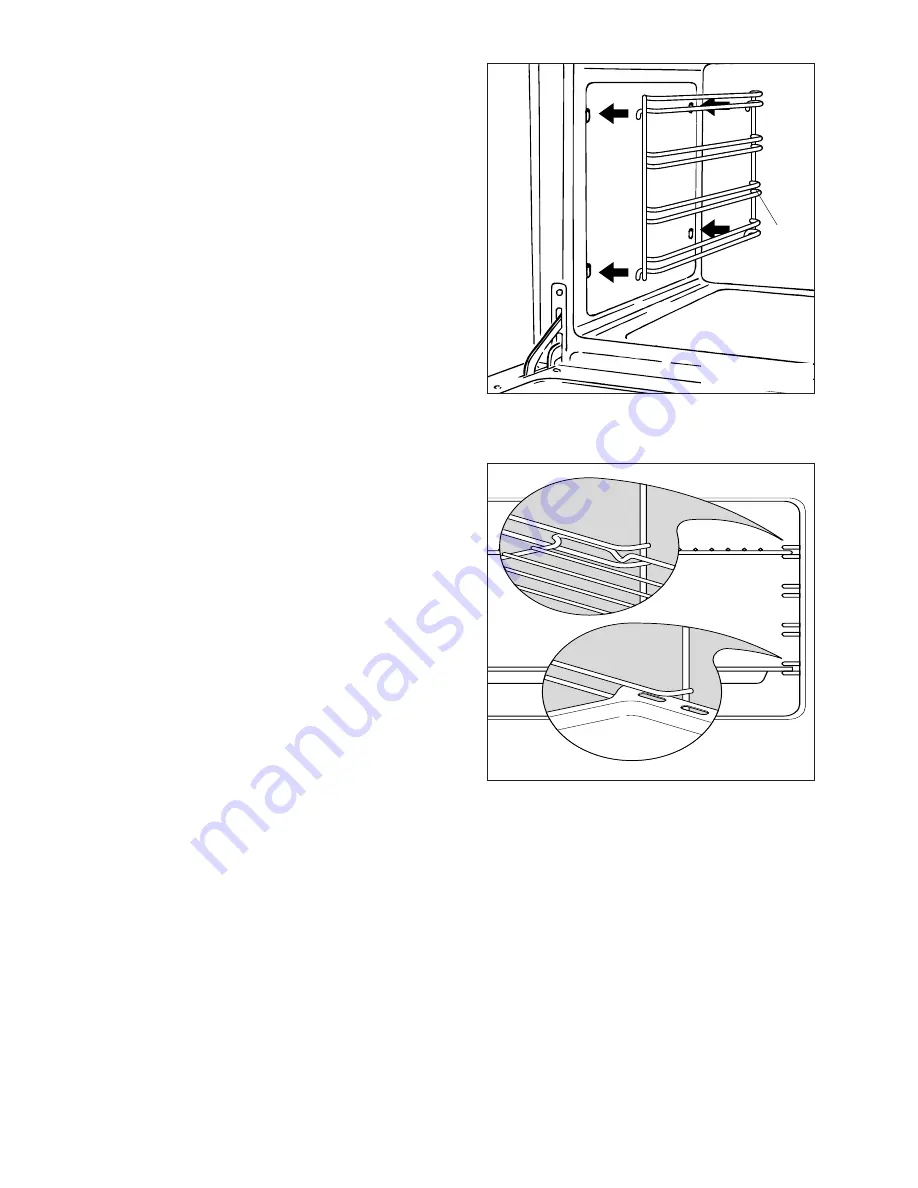

FITTING THE OVEN OUT

– Hang up the wire racks “G” on the oven

walls (fig. 8.8).

– Slide the required shelf and tray etc. in

using the guides (fig. 8.9).

The rack must be fitted so that the safe-

ty catch, which stops it sliding out, faces

the inside of the oven (fig. 8.9).

– To dismantle, operate in reverse order.

INSIDE OF OVEN

– The oven should always be cleaned

after use when it has cooled down.

– Remove and refit the side runner

frames as described on the next

chapter.

– The cavity should be cleaned using a

mild detergent solution and warm

water.

– Suitable proprietary chemical cleaners

may be used after first consulting with

the manufacturers recommendations

and testing a small sample of the

oven cavity.

– Abrasive cleaning agents or scouring

pads/cloths should not be used on

the cavity surface.

– Side runner frames, tray and rack can

be removed and washed in the sink.

NOTE: The manufacturers of this appli-

ance will accept no responsibility for

damage caused by chemical or abrasive

cleaning.

Fig. 8.8

G

Summary of Contents for CK 704

Page 1: ...Instructions for use Installation advice DUAL FUEL DOUBLE OVEN COOKER CK 704 GB ...

Page 2: ...2 ...

Page 42: ...42 ...

Page 44: ...code 1103058 ß2 ...