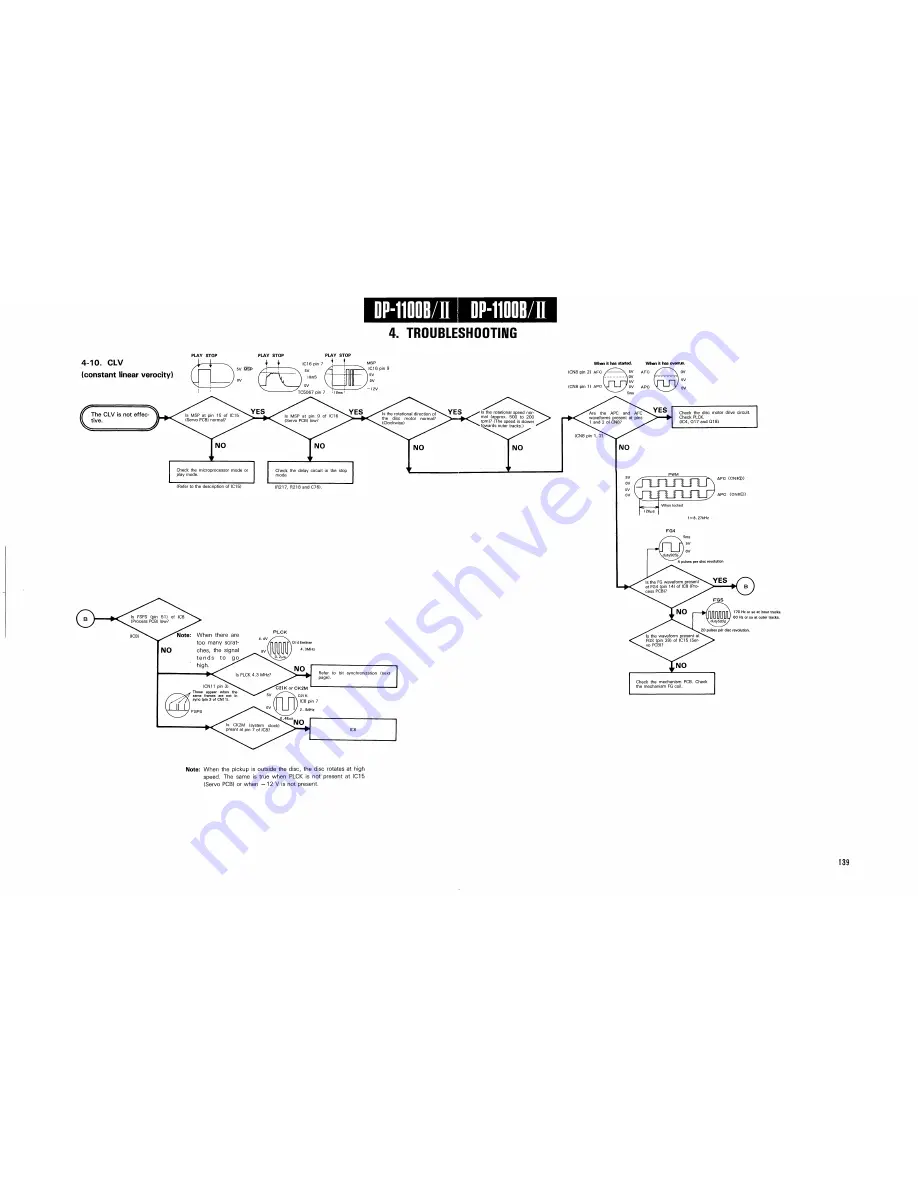

0P-1100B II DP-1100B II

4. TROUBLESHOOTING

PLAY STOP

4-10. C L V

(constant linear verocity)

The C L V is not effec

tive.

When it has started.

(CN8 pin 2) A F C

When it has overrun.

A F C / \ OV

Check the disc motor drive circuit.

Check PLCK.

(IC4, Q 1 7 and Q18)

N O

Check the microprocessor mode or

play m o d e .

(Refer to the description of IC15)

N O

r

Check the delay circuit in the stop

mode

( R 2 1 7 , R 2 1 8 and C 7 6 ) .

Note: When there are

too many scrat-

N O ches, the signal

t e n d s t o g o

high.

• Is PLCK 4 . 3 MHz?

\ Q I 4 E m i t t e r

4 . 3 M H z

(CN11

p i n

3)

T h e s e appear w h e n t h e

s a m e f r a m e s are n o t i n

s y n c (pin 3 o f C N 1 1 ) .

1 7 0 Hz or s o a t inner t r a c k s .

6 0 Hz or so a t o u t e r t r a c k s .

Check the m e c h a n i s m PCB. Check

the mechanism FG coil.

Note: When the pickup is outside the disc, the disc rotates at high

speed. The same is true when PLCK is not present at IC15

(Servo PCB) or when - 1 2 V is not present.

I 3 9

Summary of Contents for DP-1100 B

Page 3: ...D P 1 1 0 0 B II D P 1 1 0 0 B II I BLOCK DIAGRAM ...

Page 32: ...D P 1 1 0 0 B II 1 CIRCUIT DESCRIPTION Disc Scratch Dust RFES D C O N D O C K Fig 1 2A 3 5 ...

Page 112: ...2 IC OPERATION OF EACH CIRCUIT AND D P 1 1 0 0 B II PIN DESCRIPTION Fig 2 4 1 G 1 ...

Page 117: ...DP 1100B II I OPERATION OF MAIN MICROPROCESSOR Fig 3 1D Q data reading flow chart ...