MDX-G1

5

CIRCUIT DESCRIPTION

1. The recording start addresses of IN, MID, and OUT are

described below.

IN

30H cluster

MID 300H cluster

OUT 700H cluster

2. An erasure prevention control is not detected in the test

mode. Be careful not to enter the continuous recording

mode using a disc containing the data that should not be

erased.

3. Do not record continuously for more than five minutes.

4. Take care that no vibration is applied during continuous

recording.

6. ELECTRICAL ADJUSTMENT

6-1 Precaution during confirmation of Laser

Diode emission

During adjustment, do not view the emission of a laser

diode from just above for confirmation. This may dam-

age your eyes.

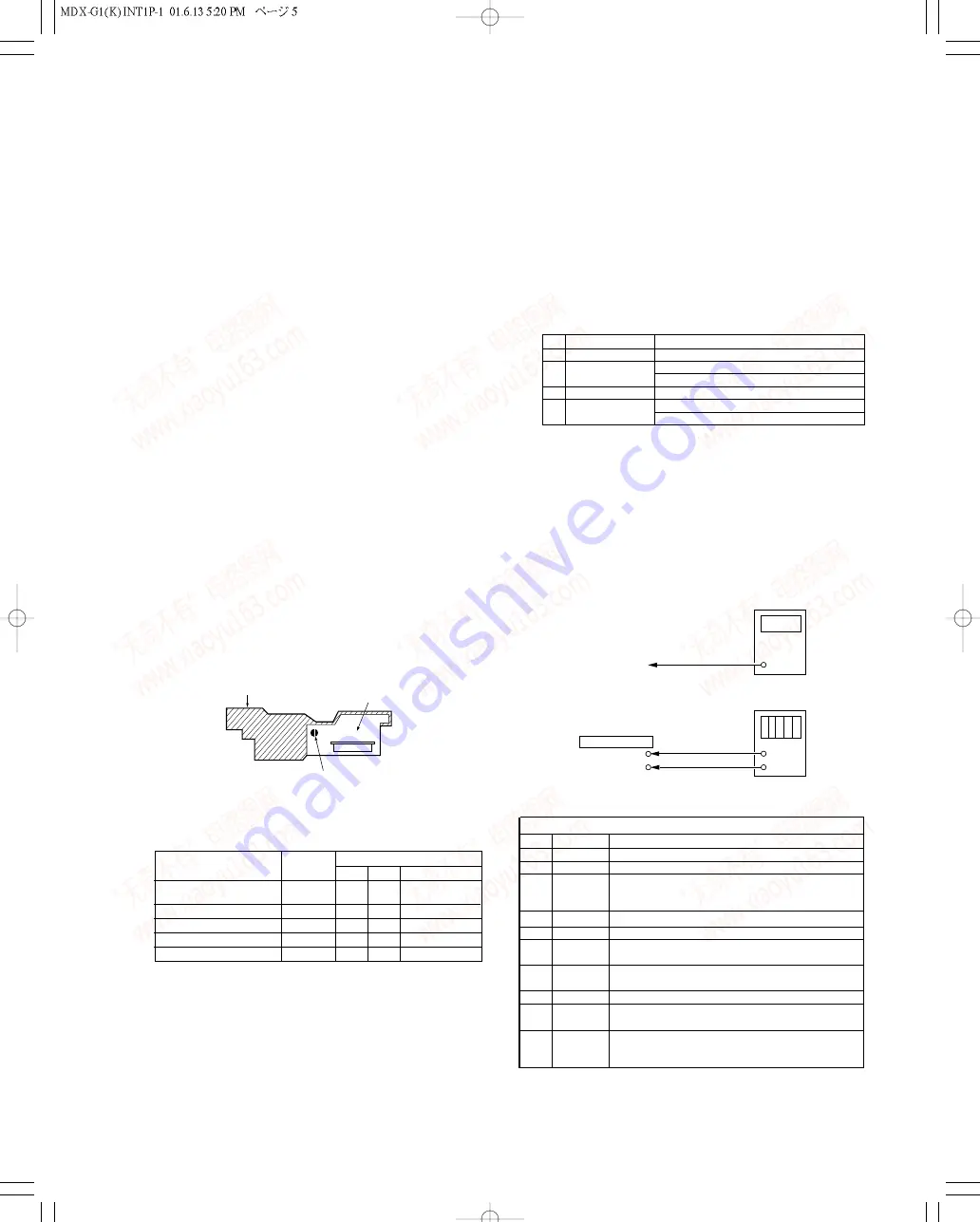

6-2 Precaution on handling of Optical pick-up

(KMS-260B)

The laser diode in an optical pick-up is easy to be sub-

ject to electrostatic destruction. Therefore, solder-

bridge the laser tap on the flexible board when han-

dling the optical pick-up.

When removing the flexible board from the connector,

make a solder bridge in advance, then remove the

board. Be careful not to remove the solder bridge before

inserting the connector. Moreover, take careful mea-

sures against electrostatic destruction. The flexible

board is cut easily. Handle the flexible board with care.

6-3 Precaution during adjustment

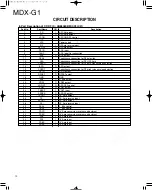

1) Perform the adjustment and confirmation marked with “O”

in the order shown in the table when the parts below are

replaced.

2) In the test mode, perform the adjustment. After adjust-

ment is completed, cancel the test mode.

3) Perform the adjustment in the order described.

4) Use the following tools and measurement equipment.

• CD test disc TGYS-1

• Laser power meter

• Oscilloscope (with bandwidth of more than 40 M

Ω

)

(Calibrate the probe before measurement.)

• Digital voltmeter

• Thermometer

5) Take care that VC and GND (ground) are not connected

on the oscilloscope when two or more signals are moni-

tored on the oscilloscope. (VC and GND are short-circuit-

ed in this case.)

6-4 Creating the recordable continuous recording

disc

This disc is used for focus bias adjustment and error rate

confirmation. How to create the recordable continuous

recording disc is 4-6.

BD board

IC7

D3

IC1, IC2, IC6

O

O

O

O

X

O

O

X

O

O

X

O

O

X

O

Pick-up

Flexible board

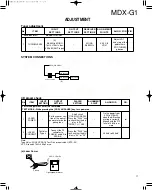

6-5 Offset Adjustment

No.

Key

Display/Function

1

4 ¢

Select [TEMP ADJU]

2 MD

6

[TEMP=xx (yy)]

(xx=compensation data, yy=setting temperature)

3

4 ¢

Input "yy" with present temp..

4 MD

6

[TEMP=

✽✽

SAVE] in writing data

[TEMP ADJU ST]

6-6 Laser Power Check and Adjustment

Laser power setting in playback and recording modes.

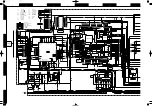

Preparation

1. Remove the MD mechanism from the unit.

2. Connect the digital voltmeter to TP1 and TP2 on X33 pcb.

3. Remove the top plate from traverse unit.

4. Remove the magnetic head.

5. Remount the MD mechanism to the unit

+

-

Laser

power meter

Digital

voltmeter

Objective lens of

optical pick up

TP2

TP1

X33

ADJUSTMENT

1. Laser Power Adjustment

No.

Key

Display/Function

1

4

¢

[LDPWR ADJU]

Load recordable disc

2

Load the disc and lazer on

[(a0.9mW) $xx] read power

(xx=power value)

4

3

EJECT

MD

6

Unload the disc and laser on

5 MD

6

[LDPWR CHECK]

6

1

¡

Move the pickup to check the laser power with

laser power meter sensor

7

4

¢

Adjust "xx" so that the power meter shows 0.9mW.

8 MD

6

[(a7.0mW) $xx] writing power

9

4

¢

Adjust "xx" so that the power meter shows 7.0mW.

This adjustment should be carried out in 15 secs.

10 MD

6

Laser power off

Display shows [LDPWR ADJUST] after [LDPWR<$xx]

to save the data in E2PROM

Start from No.2 if readjust.

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299