08/06

Section 4

Body Mounting

4-4

frame Sill

If the body is mounted to the frame with brackets, we recommend that the frame sill spacer be made from a strip of rub-

ber or plastic (delrin or nylon) These materials will not undergo large dimensional changes during periods of high or low

humidity The strip will be less likely to fall out during extreme relative motion between body and chassis See Figure 4–3

figure 4-3.

Spacer Between Frame Sill and Body Rail - Rubber or Plastic

Brackets

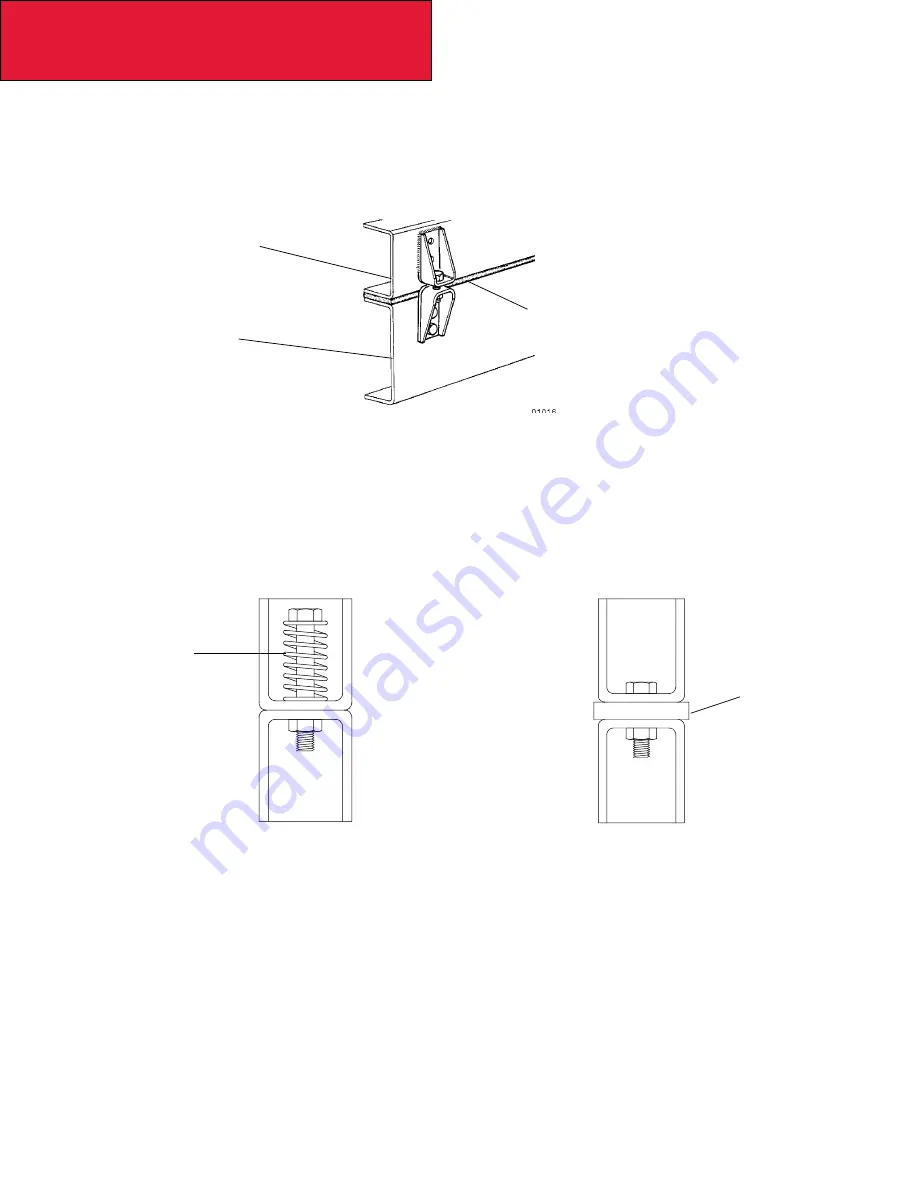

when mounting a body to the chassis with brackets, we recommend designs that offer limited amount of relative move-

ment, bolted securely but not too rigid Brackets should allow for slight movement between the body and the chassis For

instance, Figure 4–4 shows a high compression spring between the bolt and the bracket

figure 4-4.

High Compression Spring

figure 4-5.

Rubber Spacer Between Brackets

Between the Mounting Bolt and Upper Bracket

Another possibility is mounting a rubber spacer between the brackets See Figure 4–5

These designs will allow relative movement between the body and the chassis during extreme frame racking situations

Extreme frame racking, and mountings that are too rigid, could cause damage to the body This is particularly true with

tanker installations

Body Subframe

(Rail)

Chassis Frame

(Rail) Sill

Spacer

Spring

Rubber Spacer

Summary of Contents for T470

Page 1: ...Kenworth T470 Body Builder Manual ...

Page 2: ......

Page 3: ...Kenworth T470 Body Builder Manual ...

Page 8: ......

Page 10: ......

Page 14: ......

Page 38: ...Section 3 Dimensions 08 09 3 24 Watson Chalin Atlas 22 5K Non Steerable Pusher ...

Page 74: ......

Page 91: ...08 06 Section 6 Electrical 6 17 5 Push down to unhook connector from switch ...

Page 109: ...08 09 ...

Page 110: ...08 09 Kenworth Truck Company P O Box 1000 Kirkland WA 98083 425 828 5000 ...