249

16.24 Matsushita FP (Aromat)

16.24.1 HMI Setting

Communication parameters must be set the same as those of the PLC. The following settings are recommended.

Parameter

Recommended Setting Notes

Serial I/F port

RS232

Options: RS232, RS485 – Dependant on PLC hardware

Baud rate

9600

Options: 9600, 19200, 38400, 57600, 115200 - Must match PLC port

setting

Parity

Odd

Options: Odd, Even, None - Must match PLC port setting

Data bits

8

Options: 7, 8 - Must match PLC port setting

Stop bits

1

Options: 1, 2 - Must match PLC port setting

HMI station No.

0

Not used

PLC station No.

1

Must match PLC port setting (0-255)

Note:

FP3 must set 0

Comm. delay (10msec) 0

Request delay: 0~999 @10 milliseconds. Use when the PLC requires a

delay between requests. Not implemented in simulation mode.

16.24.2 PLC Setting

Communication parameters must be the same as those of the MMI.

Compatible with:

FP Sigma, FP0, FP1, FP2, FP2SH, FP10SH and FP3

16.24.3 Wiring

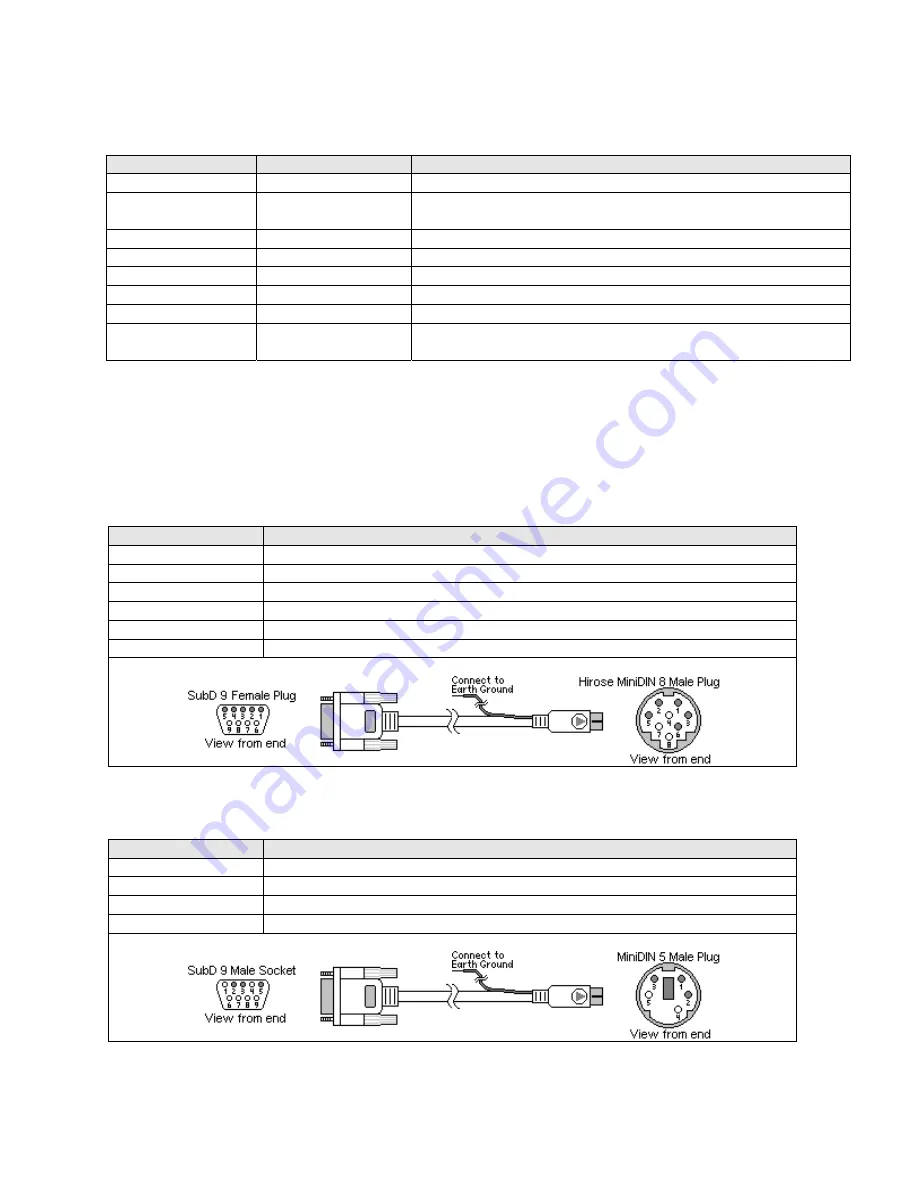

16.24.3.1

Wiring for cable connections using

Matsushita FP1 CPU’s

with Hirose MiniDIN RS422 ports.

KEP Part#: (Not Available) (D-Sub 9 Female Plug to Hirose MiniDIN 8 Male Cable)

HMI PLC[RS-485]

Connect to Matsushita FP1 CPU Port

1 RXD-

Æ

5 TXA-

2 RXD+

Æ

2 TXB+

3 TXD-

Æ

3 RXA-

4 TXD+

Æ

6 RXB+

5 GND

Æ

1 GND

Shield

Æ

Earth Ground

16.24.3.2

Wiring for cable connections using

Matsushita FP Sigma, FP0, FP2, FP2SH,

FPM CPU’s

with RS232 MiniDIN 5 ports.

KEP Part#: (Not Available) (D-Sub 9 Male Socket to MiniDIN 5 Male Cable)

HMI PLC[RS-232]

Connect to Matsushita FP Sigma, FP0, FP2, FP2SH or FPM CPU Port

2 RXD

Æ

5 TXD

3 TXD

Æ

3 RXD

5 GND

Æ

1 GND

Shield

Æ

Earth Ground

Summary of Contents for MMI-1500

Page 2: ...ii...