70

8

/ 7

48

/

89

8

68

0

/ 7

20

/

87

0

Liftin

g lim

it

!

Up Down

Up Down S

!

Up Down

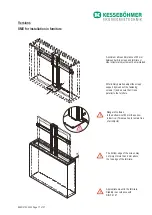

Standard drive technology - please use

infrared remote control

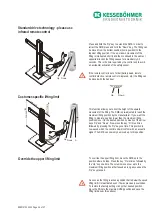

Costomer-specific lifting limit

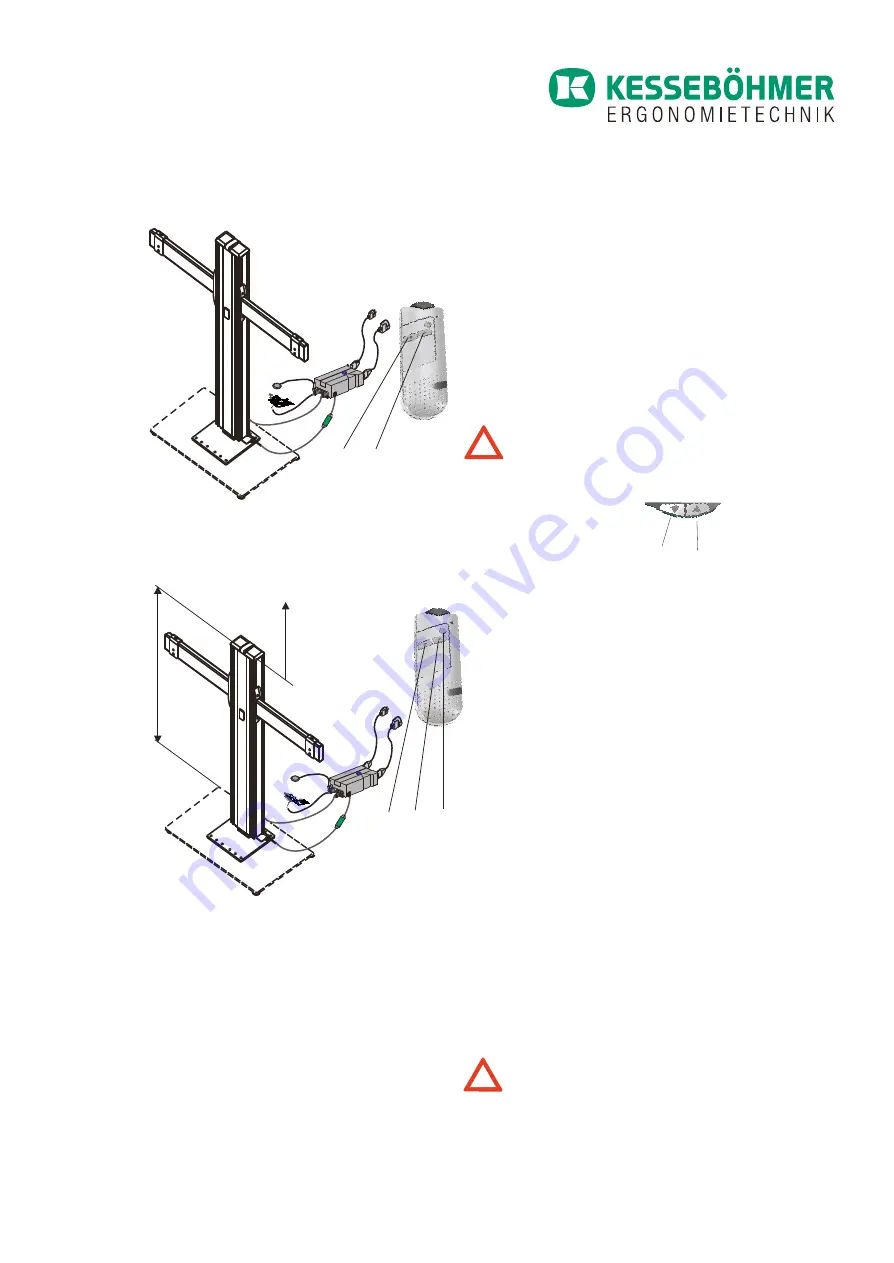

Override the upper lifting limit

Press and hold the “Up” key to extend the SME. In order to

retract the SME, press and hold the “Down” key. The fitting can

be moved from the bottom position (home position) to the

topmost lifting position. If the up or down movement of the

fitting is interrupted shortly and then continued in the same or

opposite direction the fitting pauses for a mandatory 2-3

seconds. This is the time required by the control unit to avoid

an accidental activation of the safety sensor.

If the remote control is out of order (battery dead, remote

control defective, remote control misplaced, etc.) the fitting can

be moved with the handset.

This function allows you to limit the height of the upward

movement of the fitting. The SME is pre-adjusted to reach the

maximum lifting position by the manufacturer. If you want the

fitting to stop at a position lower than the maximum lifting

position move it to the desired position by means of the arrow

keys “Up” and “Down”. Now press the key “S” three times

followed by pressing the “Up” key one time. This position is

now saved which the control unit will confirm with an acoustic

signal. The SME can now only be moved up to this position.

To override the upper lifting limit, move the SME up to the

position where it stops. Press the key “S” six times followed by

the “Up” key one time. The column moves now up to the

maximum lifting position at half speed as long as you keep the

“Up” key pressed.

As soon as the fitting reaches a position that is below the saved

lifting limit it is reactivated even if it was previously overridden.

To restore the factory setting or any other desired position

move the fitting to the maximum lifting position and save the

lifting limit anew. (See above)

889012120 0000 Page 24 of 27