889012120 0000 Page 15 of 27

Foreword

Dear customer,

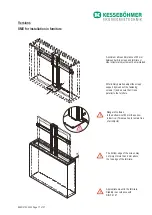

In choosing a ScreenMotion

Basic model,

you have decided to acquire a technically advanced and powerful

motor-driven guide column. Your ScreenMotion Basic has been manufactured inhouse with the utmost care and

precision and has passed numerous quality and safety checks to ensure trouble-free and safe operation. You can

significantly contribute to your long-term satisfaction with your ScreenMotion

Basic model.

Important Safety Information

1. Assembly and operation of the motor-driven guide column must be in accordance with these assembly

instructions – otherwise there is a risk of injury!

2. The guide column is solely intended to serve as entertainment solution for living room, bedroom and

conference room furniture in accordance with the weights and measurements given in these instructions. Any

usage other than that mentioned above is inappropriate; the manufacturer disclaims liability for any resulting

damages. In such cases all risk is carried by the user.

3. Before any downward movement the space in the furniture compartment must be checked. There must not be

any persons, animals or objects in the compartment.

4. The column must be abled to move into bottom position at all times. When mounting the TV set and running

the cables it is important to ensure that these do not interfere with reaching the bottom position.

5. Compliant with emission class 1 for particleboards. No emission of harmful substances pursuant to Safety Data

Sheet; no emission of harmful substances in harmful concentrations.

6. The intended operation of the device implies compliance with the assembly instructions stipulated by the

manufacturer.

7. Please also take into account the general legal and other regulations and legal provisions that are applicable –

including those that apply in the operator’s country - as well as the applicable environmental protection

regulations. The regulations of trade associations or other supervisory authorities that are in force locally must

always be observed!

8. The manufacturer cannot be held responsible for any losses or damage resulting from unauthorised

modifications to the ScreenMotion Basic.

9. Never open the control unit housing! As a result of unauthorised opening of the housing and improper repairs

dangers can arise for the user and the guarantee claim expires.

10. Repairs may only be carried out by personnel working for or licensed by the manufacturer!

11. Do not allow any liquid to penetrate the inside of the control unit or the lift column. This could lead to short

circuiting and destruction of control elements. Controls may only be operated in enclosed areas. Do not use

in humid environments.

12. The control unit and lift column may only be used for the purposes outlined in these assembly instructions.

13. Please first check whether cable or housing are damaged. In this case do not operate the device but have it

replaced by your service partner.

14. The control unit is only suitable for operation in enclosed and dry living and office rooms. It may not be used

outdoors.

15. Do not connect electric devices with a power consumption of over 800 watts to the live outlet (socket).

16. Do not connect electric heating devices, fan heaters, radiators or power tools such as drills, jigsaws or similar

devices to the live outlet (socket).

17. The control unit may only be used for the operation of Kesseböhmer drives.

18. Keep other objects away to eliminate any danger of jamming or crushing them.

19.

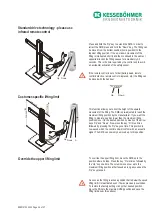

Function of safety sensor:

-

The sensor is not activated until one second after the start of any movement.

-

After the safety sensor is activated a pause of ca. 5 sec. needs to be observed until the swaying of the

fitting stops.