11

5. Installation

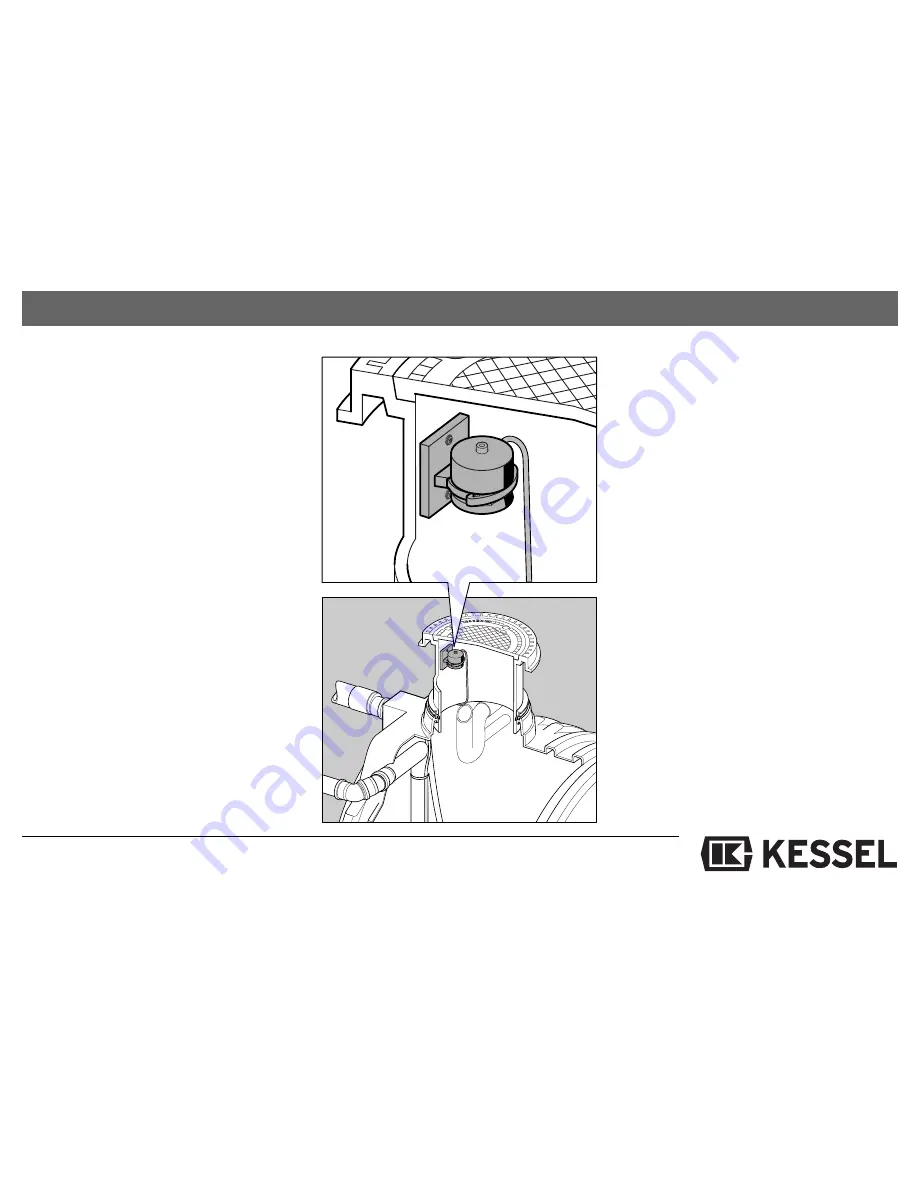

5.2 Ultrasound sensor installation

the following must be noted:

"Safety instructions" chapter

Handle the ultrasound sensor with care

Do not damage the sealing rubber bet-

ween the attachment and tank

The ultrasound sensor must be aligned

perpendicular to the surface of the

water. The maximum deviation is 2°

Ensure there are no objects between the

ultrasound sensor and the surface of the

water (e.g. ball of the floating extractor)

The distance between the bottom edge

of the sensor housing and the highest

water level in the tank must be greater

than 20 cm

The levels and switching points in the

tank (see following diagrams)

The ultrasound sensor must be secured

with the bracket.

The connection cable must be secured

with strain relief (cable grip).

5.3 Installing the leakage probe

Note and follow the "Safety

Instructions" chapter!

Install the leakage probe as given in the

original operating instructions.