e300i User Manual

Document #: 0503M01A

REV : 1.3

Approval:

Date: March ’08

Page 9 of 25

3.

3.

3.

3.7

7

7

7 Tail Assembly

Tail Assembly

Tail Assembly

Tail Assembly (if not factory assembled)

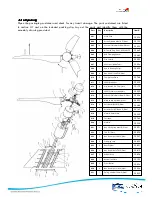

Offer the tail boom (05) to the rear of the generator and align the three inner fixing holes with

the inner studs. Fasten the boom to the rear of the generator with the three M8 Nylock nuts (18).

Now fit the four lower bolts (20), washers (19) and nuts (18) on to the

generator sides by means of the side bars. Level the boom with the

generator, secure the bolts through the rubber bushes so that the boom is

held in place and tighten all fastenings to the required torque setting (see

3.4 Pg 7).

Slide the nacelle cover (0730) along the boom so that it is

covering the generator. Secure the nacelle cover to the rear of the

generator with the two M6 screws to the required torque setting

(see 3.4 Pg 7). Slide the front closing plate between the underside

of the generator and the nacelle cover and secure with the four

M5 screws to the required torque setting (see 3.4 Pg 7) through

the holes provided.

Fasten the tail (07) upper and lower halves to the boom with the ten

stainless bolts (23), stainless flat washers (24) and with the ten stainless

Nylock nuts (23) provided. Now fit the tail stabilisers, two on each side

of the tail using the one longer stabiliser bolts (27) through the tail

boom and the middle of each stabiliser on either side. The other two

stabiliser bolts (26) are fitted through the tail with the washers (28)

and nuts (29) at each end of each stabiliser.

Do not over-tighten such that the tail boom is crushed or distorted

.

Always adhere to the torque

settings provided.

Check once again that all bolts are fitted and tightened to torque settings (3.4).

9