Atfinger Technology Co.,Ltd.

STC-1000

Temperature Controller

Operating Manual

1.

Overview

•

Switch between heat and cool.

•

Support delay start and temperature calibration.

•

Alarm when temp exceed temperature limit or sensor error

•

All parameters setting can be saved after short circuit.

•

Refrigerating control output delay protection

•

Can be used for domestic freezer, water tanks, refrigerator,

industrial chiller, steamer, industrial equipment and other

temperature-controlled system.

2.

Specifications

•

Power Supply: AC90~250V 50/60HZ/ DC12V/ DC24V

•

Temperature control range: -50~99

°

C

•

Difference Set Value: 0.3~10

°

C

•

Accuracy:

±

1

℃

(-50

℃~

70

℃

)

Resolution : 0.1

°

C

•

Sensor error delay:1 minute

•

Measuring input: NTC(10K0.5%) Waterproof sensor 1m

•

Relay contact capacity: Cool Heat(10A/250VAC)

•

Ambient temperature: -20-70

°

C , humidity 20% -85%RH

•

Size: 75mm(L)*34mm(W)*85mm(Depth)

•

Mounting size: 71(L)*29(W)mm

•

Power consumption:

≤

3W

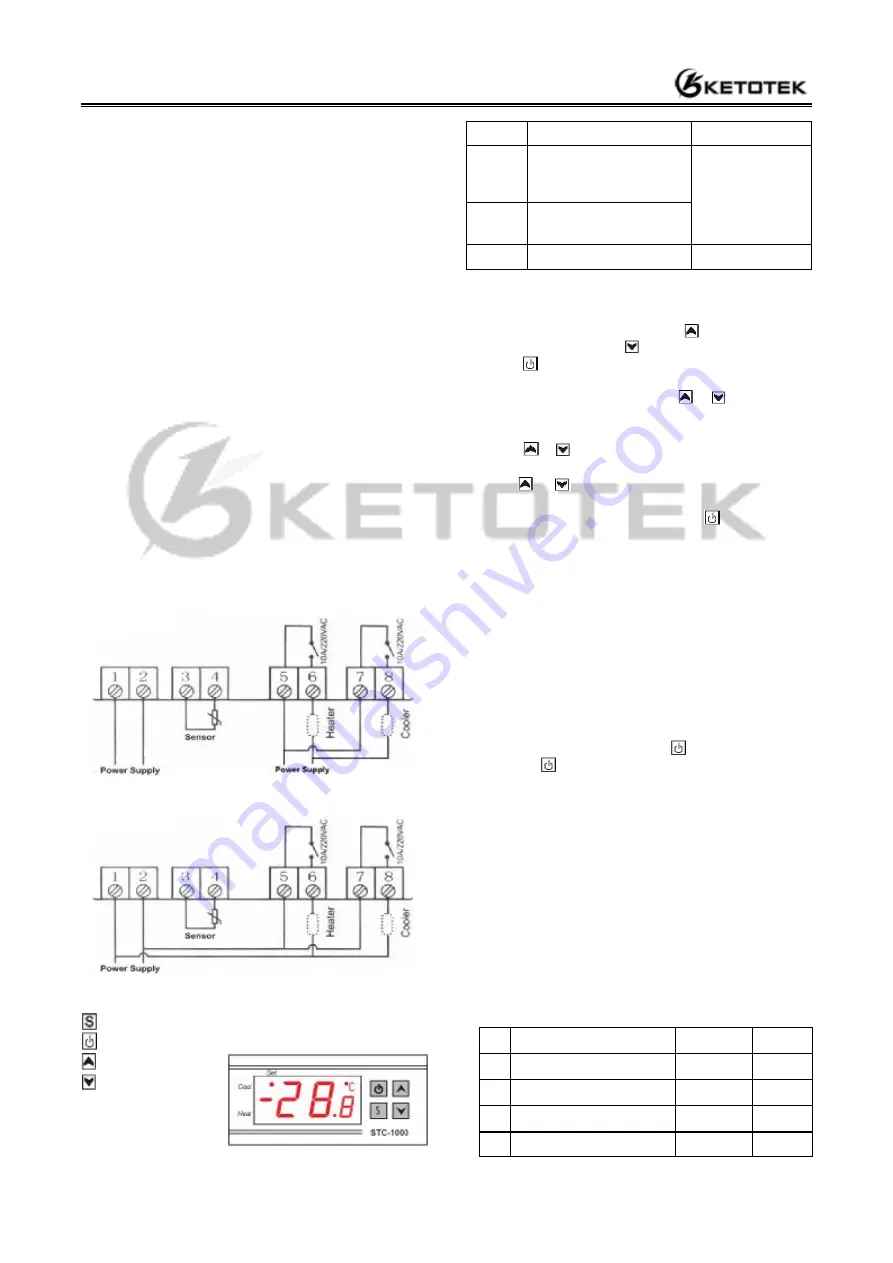

3.

Wiring Diagram

Connection 1:Independent power supply for load

Connection 2:Same power supply for load

4.

Key Instruction

:Set key,Confirm the setting value,Entry and Set parameter.

:powr on/off, or quit the setting.

:increase value

:

decrease value

Cool

:cool output indicator

Heat

:heat output indicator

Set

:Setting indicator

5.

Key Operation Instruction

•

Check parameter:

In normal working status, the screen

display real time temperature.press

. it dispay the setting

temperature value.press

. it dispay the difference value.

Press

to back to normal display.

•

Set parameter:

In normal working status, press

S

for 3s to

enter set parameter mode. Press

or

to switch from

F1-F4.(see menu code table). Press

S

to display the

parameter set value of the current code.Press and hold

S

,

Press

or

again to adjust up and down the parameter

setting value of the current code. Press and hold both

S

and

or

simultaneously to choose and adjust the

parameter value of the current menu value promptly.After

finishing the setting,press and release

instantly to save

the parameter modified value and return to normal display.

If no key operation within 30 seconds, system won

’

t save

modified parameter, screen back to display normal

temperature. Screen display

“

Er

”

if error appears during

parameter saving, and back to normal working status in 3

seconds.

•

Restore system data:

When electrified, system will check

itself, screen will display

”

Er

”

if error exit, please press any

key at this time, and it restore default value and enter into

normal working mode. it is advised to reset the parameter

value under this condition.

6.

Operation Instruction

•

In normal working status, hold

for 3seconds to power

off, hold

for 3seconds to power on.

•

In normal working status, the screen display

RT

(real time

temperature value). the controller can also switch the

working mode between heating and cooling.

•

①

Refrigerating starts w

hen

RT

≥

ST

(temperature set

value) +

F2

(difference value), the refrigerating relay is

connected. cool indicator flashes. it indicates the

refrigerating equipment is under compressor delay protect

status;When

RT

≤

ST

, cool indicator light off,

refrigerating relay disconnects.cooler stop working.

•

②

Heating starts w

hen

RT

≤

ST

-

F2

, heat indicator light

on. heat relay connect. When

RT

≥

ST

, heat indicator turn

off, heat relay disconnect, heater stop working.

•

For example,set 10

℃

,difference 3

℃

,heater work when

RT

≤

7

℃

.heater stop when

RT

≥

10

℃

. Cooler work when

RT

≥

13

℃

,Cooler stop when

RT

≤

10

℃

.

Indicator

Function

Notes

Heat light

On:Refrigeration starts;

Off:Refrigeration stops;

Flash:compressor delay

Cool

、

Heat indicator

light can not be

“

on

”

status simultaneously

Cool light

On: heating starts;

Off:heating stops

Set light

On:parameter setting status

Code

Function

Set Range

Default

F1

Temperature set value

-50

~

99

℃

10

℃

F2

Return Difference

1

~

10

℃

3

℃

F3

Compressor delay time

1

~

10minute 3 minutes

F4

Temperature calibration value -10

℃~

10

℃

0

℃