53

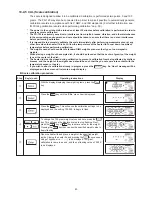

Display

Operating instructions

Completion of measurement

Measuring will be completed when the conditions specified for automatic halting

mode have been met. When measuring is completed, the bias will be displayed

in the bias display area.

*

If no predicted measurement is displayed even after 30 minutes has elapsed

from the time when measuring was initiated, it is probable that it is impossible

to obtain a predicted measurement.

[Measurement results]

Predicted measurement

Automatic halting mode measurement

Bias + 0.60

= 16.40 (Automatic halting mode value) – 15.80 (Predicted measurement)

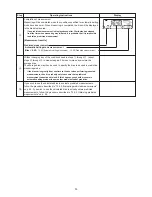

Without changing any of the conditions used in steps

1

through

5

, repeat

steps

6

through

8

to measure again 5 times or more and calculate the

average bias.

The average bias may then be used to specify the bias to be used in predictive

measuring mode.

*

If the bias varies greatly from one time to the next when performing repeated

measurements, then it is probably safe to assume that a predicted

measurement cannot be obtained. If this happens you should measure in

automatic halting mode or in some other mode instead of predictive.

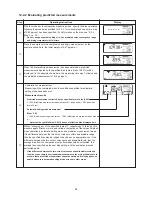

If you wish to use the calculated bias to evaluate predicted measurements,

follow the procedure described in “12-2-2 Evaluating predicted measurements”

on p. 54; if you wish to use the calculated bias to actually obtain predicted

measurements, follow the procedure described in “12-2-3 Obtaining predicted

measurements” on p. 55.

Step

8

9

0

Summary of Contents for FD-720

Page 1: ...Infrared Moisture Determination Balance FD 720 Operating Manual ...

Page 2: ......

Page 66: ......

Page 67: ......

Page 68: ...0706 PA 0201 200 ...