EN

18

3 - PRELIMINARY CHECKS

Before installing this product, verify and check the following steps:

- Check that the gate or door are suitable for automation

- The weight and size of the gate or door must be within the operat

-

ing limits specified for the automation where the product is installed

- Check the presence and strength of the security mechanical stops

of the gate or door

- Check that the mounting area of the product is not subject to flood

-

ing

- Conditions of high acidity or salinity or proximity to heat sources

could cause malfunction of the product

- Extreme weather conditions (for example the presence of snow,

ice, high temperature range, high temperatures) may increase the

friction and therefore the force required for the handling and initial

peak may be higher than under normal conditions.

- Check that the manual operation of gate or door is smooth and

friction-free and there is no risk of derailment

- Check that the gate or door are balanced and stationary if left in

any position

- Check that the power line to supply the product is equipped with

proper grounding safety and protected by a magnetothermal and

differential security device

- Provide the power system with a disconnecting device with a gap

beween contacts enabling full disconnection under the conditions

dictated by the overvoltage category III.

- Ensure that all materials used for the installation comply with cur-

rent regulations

4 - PRODUCT INSTALLATION

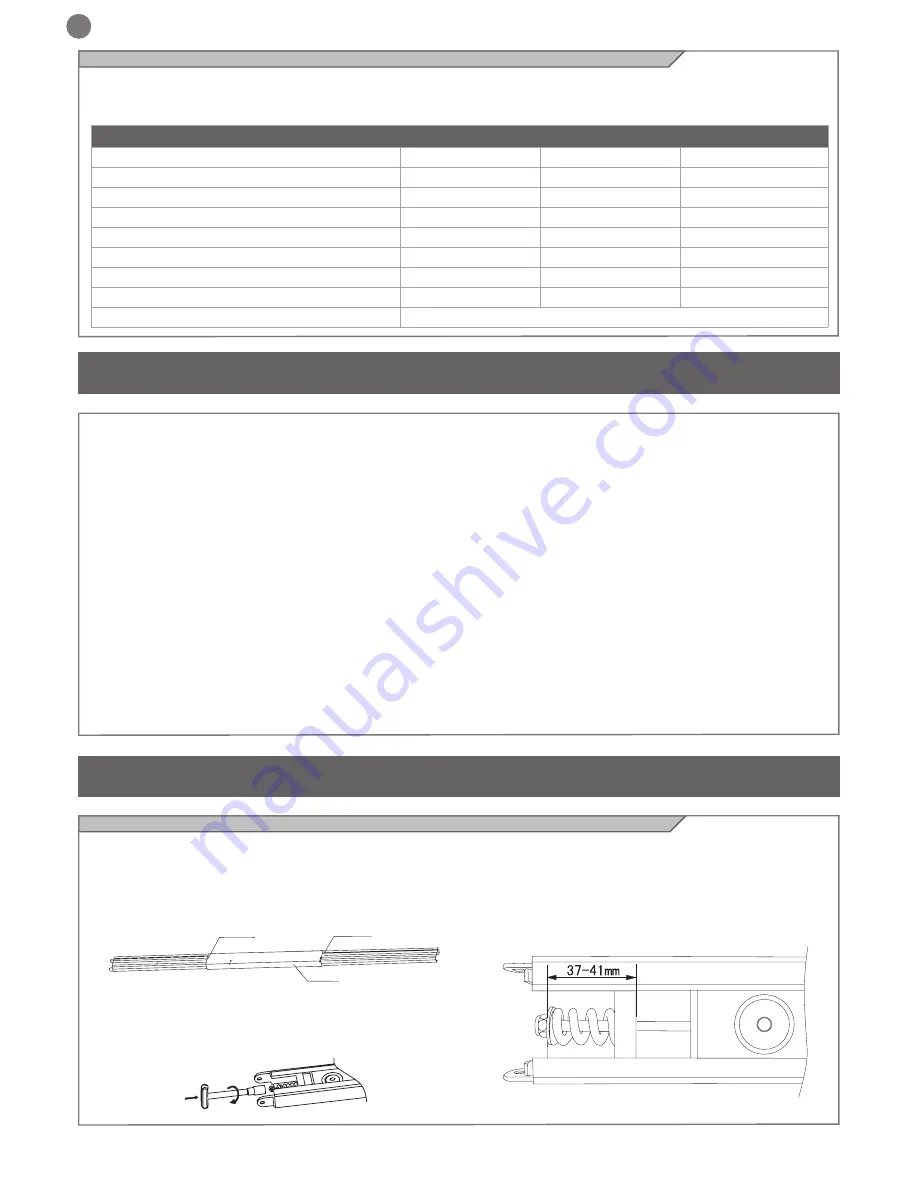

4.1

Assembly of chain in 3 parts

1. Line the three pieces of the guide

2. Place the connector at the center of the guide and between the

limits position, then repeat for the second connector.

3. Tighten the nut with a wrench Ø 13

4. Adjust as indicated in the chain draught diagram

For a correct adjustment ensure that during movement of the door

the chain does not slide out of the tracks (too loose) or on the con

-

trary tends to bend the tracks (too tight)

Limit position

Connector

Limit position

2.5 List of cables needed

Typical installation cables required for connection of various devices

are shown in cables list table.

CABLES LIST TABLE

Connection

da 1 a 10m

da 10 a 20m

da 20 a 30m

Power supply line

3 x 1,5 mm

2

3 x 1,5 mm

2

3 x 2,5 mm

2

Flashing light

2 x 0,5mm

2

2 x 0,5mm

2

2 x 0,5mm

2

Transmitter photocells

2 x 0,5mm

2

2 x 0,5mm

2

2 x 0,5mm

2

Receiver photocells

4 x 0,5mm

2

4 x 0,5mm

2

4 x 0,5mm

2

Key selector

3 x 0,5 mm

2

3 x 0,5 mm

2

3 x 0,5 mm

2

Fixed edges

2 x 0,5 mm

2

2 x 0,5 mm

2

2 x 0,5 mm

2

Mobile edges

2 x 0,5 mm

2

2 x 0,5 mm

2

2 x 0,5 mm

2

Antenna with RG58 shielded cable

RG58 Shielded cable max 10m

The cables used must be suitable for the installation; for example,

we recommend a H03VV-F type cable for indoor installation and

H07RN-F for outdoor.

about