Keysight Instrument Rack E7950A-1.3m E3661B-1.6m E3662B-2.0

27

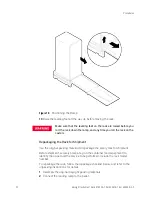

The first consideration, after leveling the rack on the leveling feet, and extending

the anti-tip mechanism, is to load the rack from the bottom to the top.

Acoustic Considerations

Airborne audible noise is a primary concern for most system configurations.

Noise from forced convection thermal management solutions such as the

extractor fan is directly proportional to the volume of air passing through the

rack.

Total system noise should be considered during the design phase, as it can

affect areas where the system can be used, operator comfort and safety, and

impact federal and regulatory agency compliance requirements for noise output.

Individual product noise can augment (increase) system noise above extractor

fan ratings due to constructive (additive) interference between various in-place

frequencies, and decrease below the extractor ratings if destructive (subtractive)

interference is present.

Total system noise is impossible to calculate completely accurately. Therefore,

system acoustic performance should be measured to ensure that acoustic goals

are met. However, assuming the worst case (constructive) noise levels, some

general estimating guidelines can be used to combine noise levels of system

products used together. Acoustic sound power and pressure data are

logarithmic (not linear). Thus:

50 dB + 44 dB = 51 dB

Below are two examples to illustrate the point.

Example 1. What is the estimated sound power output of my two-component

system if component 1 contributes 50 dB, and component 2 contributes 65 dB?

Original equation with variable x.

50 dB + 65 dB = x dB

Divide the entire equation by 10. 50/10 dB + 65/10 dB = x/10 dB

Write the equation in powers of 10 ( dB units are Log base 10 units). 10

5

+ 10

6.5

=

10

x/10

Evaluate the left side of the equation. 100,000 + 3,162,277.66 = 10

x/10

3,262,277.6 = 10

x/10

Take the log of both sides of the equation (return to dB units). log (3,262,277.66)

dB = x/10 dB

The anti-tip stabilizer is not a substitute for ballast. Use the

anti-tip mechanism when loading or unloading equipment.