22

Keysight Instrument Rack E7950A-1.3m E3661B-1.6m E3662B-2.0

Set Up

Set Up

This chapter defines the floor loading requirements and set up guidelines.

Floor Space and Loading

Observe floor loading requirements (especially raised floors) and ensure

adequate space before moving your Keysight rack, and all safety items while

moving.

At maximum gross weight, the floor must be able to support 677-kg/ sq cm

(2000 lb./sq in).

Because the weight is concentrated on the four casters, a maximum weight rack

requires a reinforced floor. Keysight Technologies recommends removing

components and moving them separately when moving a rack over a floor

(especially a raised floor) of unknown capacity.

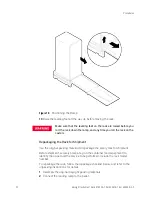

Rack Space

Select a location for the rack that will afford adequate space for the door to open

freely, and slide-mounted equipment to be extended.

The rack requires a minimum of 600 mm for rear door clearance.

Equipment Installation Guidelines

Several guidelines should be kept in mind when installing equipment into racks.

The two main considerations are weight and balance (for slide-mounted

equipment), and heat dissipation. This section includes some worksheets for

calculating the weight and balance for slide mounted products and an optional

work surface. A discussion of acoustic considerations is also included.

Always install equipment from the bottom to the top to keep the center of gravity

as low as possible. The order that you put them should be based on how well a

given piece of equipment promotes or impedes heat removal, if heat removal is

an issue.

It is the customer's responsibility to determine the floor loading

capacities at the installation site, and for the entire route when

moving. Failure to do so could result in personal injury and/or

equipment damage.

Heavily loaded racks may require may require reinforced tiles or a

structure on a raised floor.