High-Level Diagnostic Tools, Processes and References

Operational Check

This operational check procedure is used for high-level troubleshooting – a rough diagnostic to ascer-

tain if the module is functioning properly. You do not have to conduct the operational check if you

conduct the

Performance Verification Tests

(see page

).

Requirements for Operational Check

The Agilent M9360A PXI Attenuator/Preselector operational check measures the signal paths from the RF IN

connector to the RF 1 OUT and RF 2 OUT connectors. The following process demonstrates that all associated

switches, connectors, cables and circuitry are operational. The signal paths from the LO IN connector to the LO 1

OUT and LO 2 OUT connectors are also measured.

Required Hardware

To demonstrate that the module works properly requires external equipment. This includes a precision microwave

source and a power meter You will not be using the module interconnect cables, so some high-quality flexible 3.5

mm cables will be required, plus adaptors to connect the PSG (precision signal generator) and power sensors to

3.5 mm connectors. Please refer to the following table for recommended hardware.

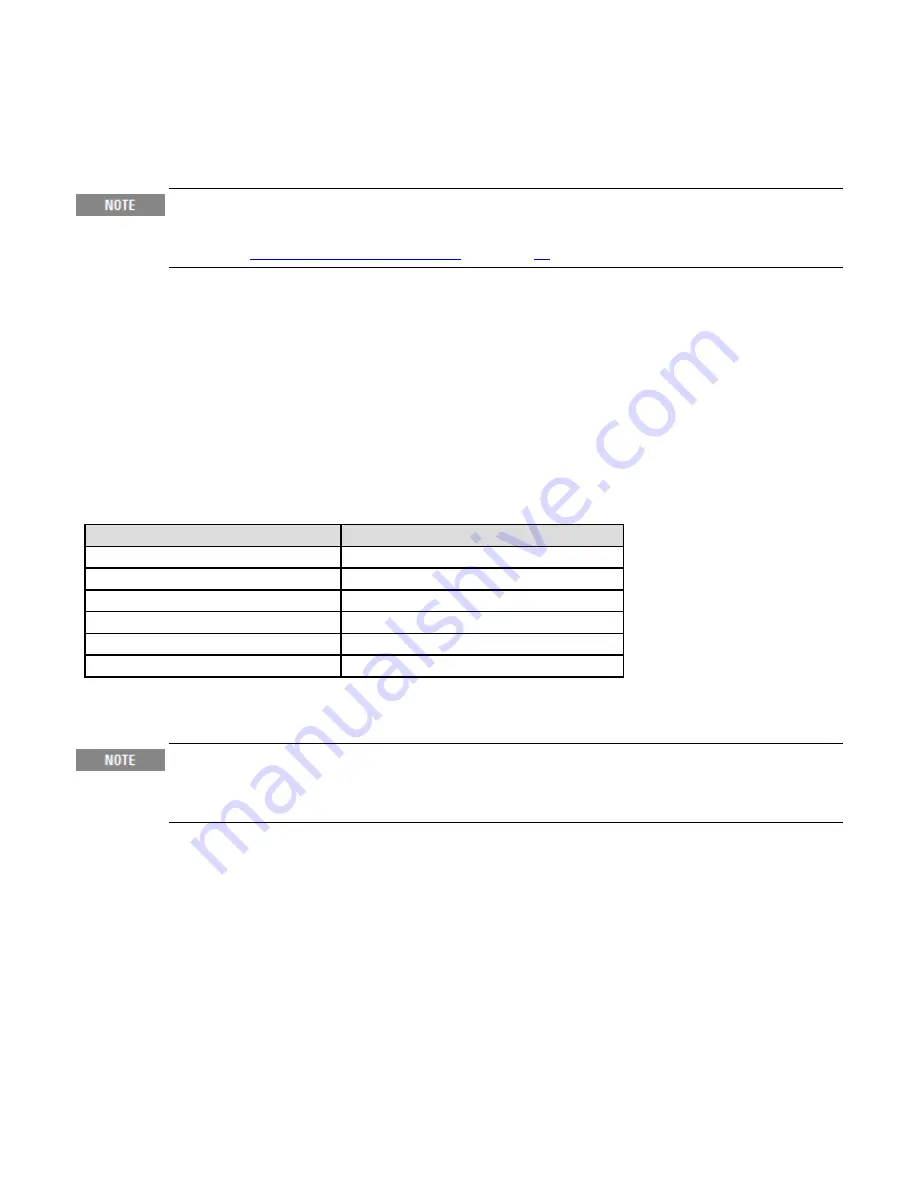

Hardware

Description

Agilent E8257D-532 or E8267D-532

Precision Signal Generator 31.8 GHz

Agilent N1913A or N1914A

Single / Dual Channel Power Meter

Agilent N8485A, Option 100

10 MHz to 26.5 GHz Power Sensor

Agilent 11730A

Power Sensor Cable

Agilent 11667B

Power Splitter

Agilent N9020A-526

Signal Analyzer (optional)

M9360A Operational Check Procedure

To use a single power meter in place of two power meters and sensors, characterize the PSG output

power at the different frequencies and then connect the PSG output directly to the M9360A RF IN.

Connect the power sensor to the outputs listed in the procedure below.

Agilent M9360A PXI Attenuator/Preselector Service Guide

19

Summary of Contents for M9360A

Page 1: ...Service Guide Keysight M9360A PXI Attenuator Preselector 100 KHz to 26 5 GHz ...

Page 2: ......

Page 7: ......