Getting Started

1

Keysight U1241AN User’s and Service Guide

25

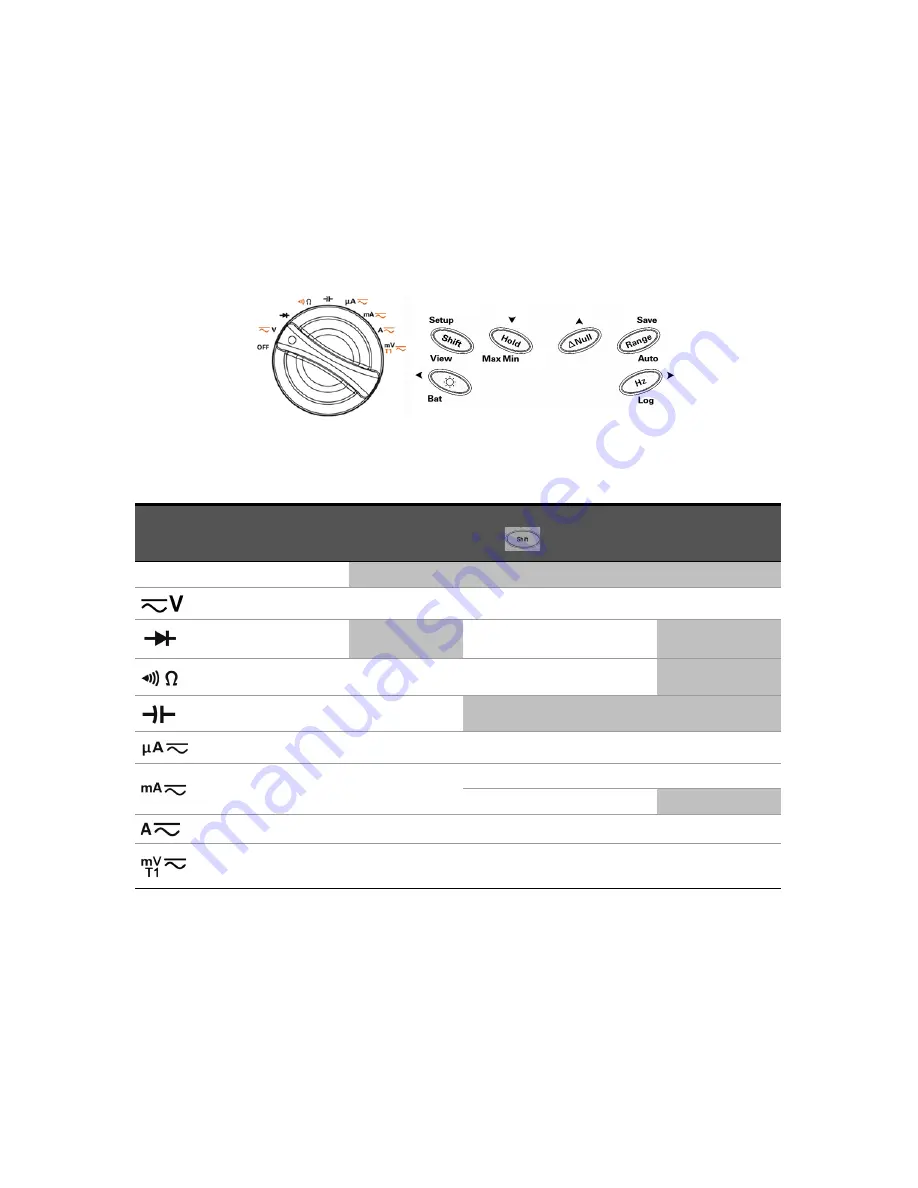

The Keypad and Rotary Switch at a Glance

Figure 1-4

U1241AN keypad and rotary switch

Table 1-4

Keypad descriptions and functions

Function

First level function

Range

Second level function(s)

(press )

Range

OFF

Power off the multimeter

DCV measurement

0.1 mV to 1000 V

ACV measurement

50.0 mV to 1000 V

Diode test

Switch counter measurement

Resistance measurement

0.01

Ω

to 100 M

Ω

Audible continuity measurement

Capacitance measurement 0.1 nF to 10 mF

DCµA measurement

0.1

μ

A to 10000

μ

A ACµA measurement

50.0

μ

A to 10000

μ

A

DCmA measurement

0.01 mA to 440 mA

ACmA measurement

5.00 mA to 440.0 mA

mA% scale

DCA measurement

0.001 A to 10 A

ACA measurement

0.500 A to 10.000 A

DCmV measurement

0.1 mV to 100 mV

T1 temperature

ACmV measurement

–40 °C to 1000 °C

0.1 mV to 1000 V

Summary of Contents for U1241AN

Page 1: ...Keysight U1241AN Handheld Digital Multimeter User s and Service Guide ...

Page 14: ...14 Keysight U1241AN User s and Service Guide THIS PAGE HAS BEEN INTENTIONALLY LEFT BLANK ...

Page 16: ...16 Keysight U1241AN User s and Service Guide THIS PAGE HAS BEEN INTENTIONALLY LEFT BLANK ...

Page 18: ...18 Keysight U1241AN User s and Service Guide THIS PAGE HAS BEEN INTENTIONALLY LEFT BLANK ...