46

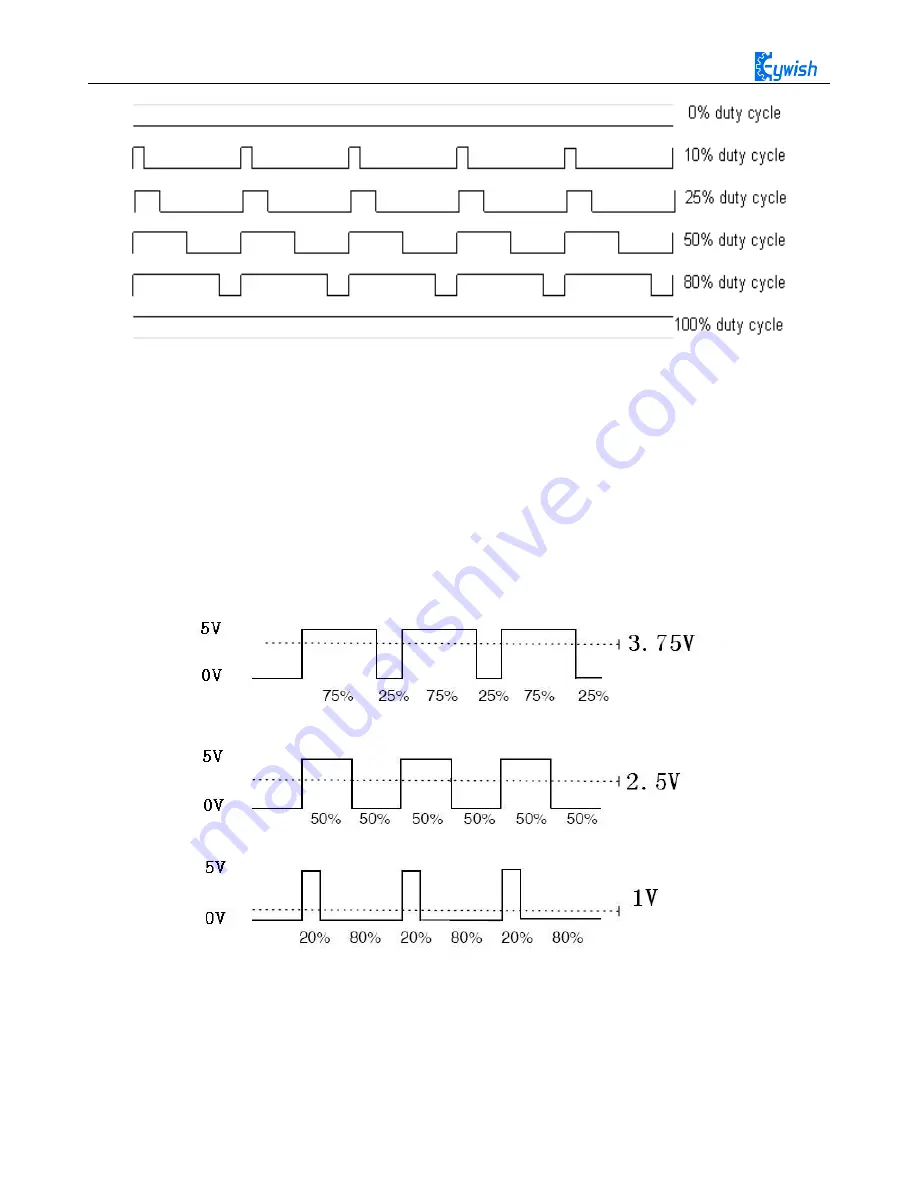

Fig.3.2.5 Sequence Diagram of PWM Duty Cycles

In Arduino, analog voltage can not be output, only 0 or 5V digital voltage value, we can use high

resolution counter and the duty cycles of the square wave modulation method to encode a specific level of

analog signal. The PWM signal is still digital, because at any given time, the full amplitude of DC power

supply is either 5V (ON) or 0V (OFF). The voltage or current source is added to the analog load with a ON

or OFF repetitive pulse sequence. When the DC power supply is added to the load, the power supply is on,

otherwise the power supply is off. As long as the bandwidth is enough, any analog value can use PWM to

encode. The output voltage value is calculated by the on and off time. Output voltage = (turn-on time / pulse

time) * maximum voltage. Fig.2.4.6 shows the corresponding voltage to the pulse change.

Fig.2.4.6 Relation between Pulse and Voltage

In the "Hummer-Bot" car experiment, we use Arduino UNO R3 as the main control board. By referring

to the chip data, we will know that Arduino UNO has 6 PWM pins, namely digital interfaces 3, 5, 6, 9, 10,

11, and we select 5, 6, 9, 10 as the motor control IO, the connection is shown in Fig.2.4.7.

Summary of Contents for Hummer-Bot

Page 1: ...Hummer Bot Instruction Manual Github https github com keywish keywish hummer bot...

Page 7: ...4...

Page 8: ...5...

Page 9: ...6...

Page 10: ...7...

Page 13: ...10 Fig 2 2 Several commonly usedArduino...

Page 15: ...12 After the completion as shown...

Page 16: ...13 The second step is to Welding wire on the motor...

Page 17: ...14 After the completion as shown...

Page 19: ...16 Fig 3 1 3 Diagram of Aluminum Alloy Bracket Installation...

Page 20: ...17 Fig 3 1 4 Diagram of Motor Installation Fig 3 1 5 Fixing Screw for Motor...

Page 24: ...21 Fig 3 1 10 Diagram of Wheel Installation Fig 3 1 10 Diagram of Wheel Screw Fixation...

Page 29: ...26 Fig 3 1 15 Diagram of Tracing Module Installation...

Page 30: ...27 Fig 3 1 16 Diagram of Screw Brackets Fig 3 1 17 The Back of Complete Installation...

Page 32: ...29 First install the screws on the UNO After the completion as shown...

Page 43: ...40 Fig 3 1 33 Diagram of Wires Arrangement Fig3 1 34 the Effect of Whole Assembly...

Page 56: ...53 Fig 3 2 11 Diagram of Data with Obstacles Fig 3 2 12 Diagram of Data without Obstacles...

Page 69: ...66 Fig 3 2 22 Diagram of Steering Gear Fig 3 2 23 Composition of Steering Gear...

Page 93: ...90 Fig 3 2 42 Receiving Head Position Fig 2 3 43 Installation of Receiving Head...