3

INSTALLATION, OPERATION AND CARE OF

CHEESE MELTER

GENERAL

Cheese melter are produced with quality workmanship and materials. Proper installation, usage, and

maintenance of your Cheese melter will result in many years of satisfactory performance.

It is suggested that you thoroughly read this entire manual and carefully follow al l of the

instructions provided.

Product parameter:

Model

BTU

Orifice size

Regulator pressure

Nat.

LP

Nat.

LP

36

”Cheese melter

33,500

#31

#52

5”WC

10”WC

THIS APPLIANCE IS EQUIPPED FOR NATURAL GAS.

For Natural gas when equipped with No. #31 drill size orifice.

For LP gas when equipped with No.#52 drill size orifice.

For conversion to LP gas orifice see instruction plate on the appliance, see Page 11.

INSTALLATION

Before installing, verify that the type of gas supply (natural or propane) agrees with the

specifications on the rating plate located underneath the Cheese melter rack drip tray. If the

supply and equipment requirements do not agree, do not proceed with the installation. Contact

your dealer immediately.

UNPACKING

Immediately after unpacking, check for possible shipping damage. If the Cheese melter is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Before installing, verify that the type of gas (natural or propane) and the clearance dimensions (see below)

agree with the specifications on the rating plate which is located under the crumb tray on the right side.

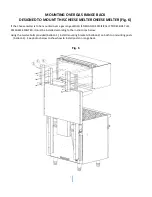

LOCATION

The equipment area must be kept free and clear of combustible substances.

Minimum Clearance

Combustible Construction

Non-Combustible Construction

Rear

2”

0”

Sides

2”

0”

Bottom

0”

0”