22

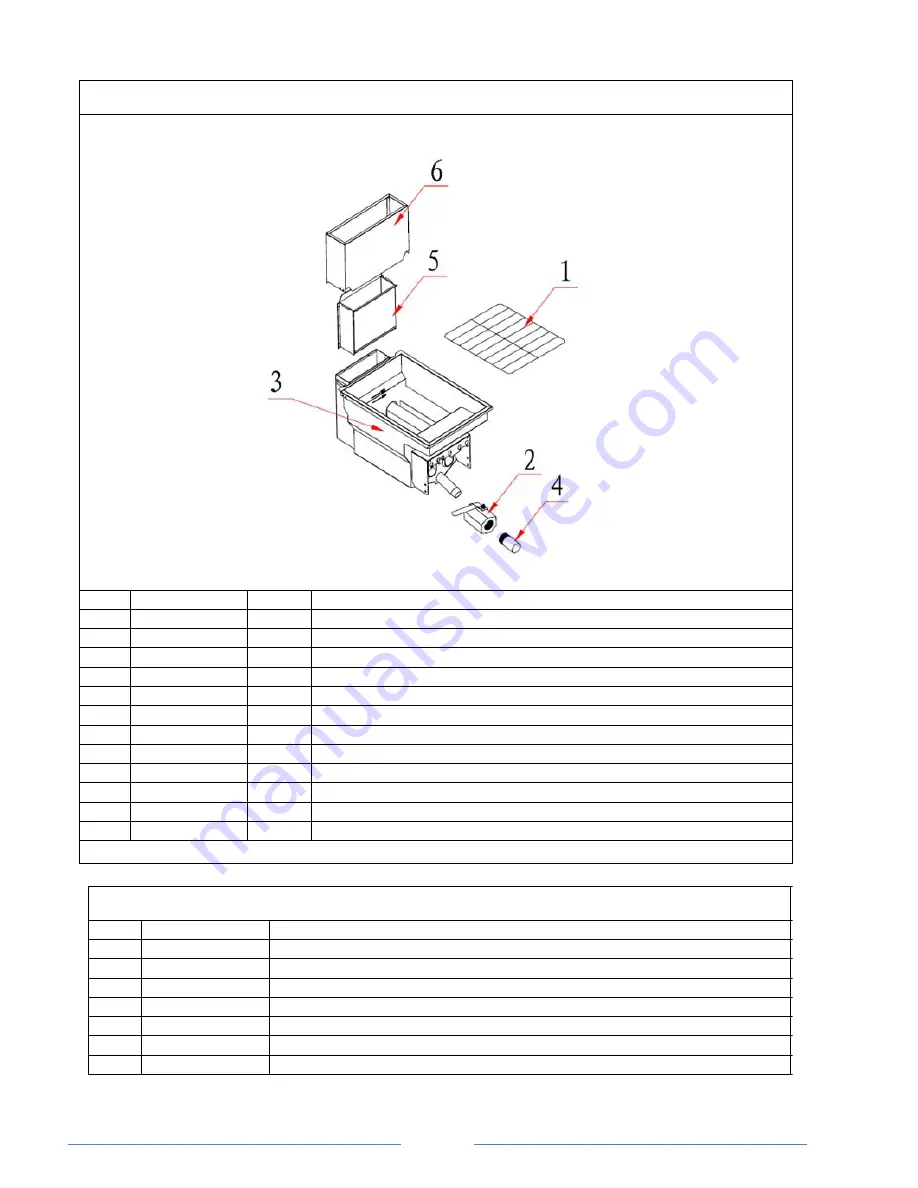

Tank Parts (3 tube shown)

Key

Part Number

Qty

Description

1

400037

1

Screen, crumb, 3 and 4 tube fryer

*

400058

1

Screen, crumb, 5 tube fryer

2

400036

1

Valve, Ball

3

C200016

1

Tank, 3 tube fryer (excluding flue)

*

C200017

1

Tank, 4 tube fryer (excluding flue)

*

C400056

1

Tank, 5 tube fryer (excluding flue)

4

400071

1

Drain, extension

5

400075

1

Flue, top, removable, 3 tube fryer

*

400076

1

Flue, top, removable, 4 tube fryer

*

400077

1

Flue, top, removable, 5 tube fryer

6

400078

1

Flue, wrap, top, removable, 3 and 4 tube fryer

*

400079

1

Flue, wrap, top, removable, 5 tube fryer

*not shown

Other Parts

Key

Part Number

Description

1

100106

Door assembly, complete, 3 and 4 tube

2

100137

Door assembly, complete, 5 tube

3

C400000

Leg Kit, 6”, adjustable, set of 4 with mounting hardware

4

C400108

Caster Kit, 4”, adjustable, set of 4 (two w/brake and two w/o brake)

5

497296-2

Magnet door

6

400038

Basket double, 3 and 4 tube fryer

7

400039

Basket double, 5 tube fryer

Summary of Contents for KF-F3-LP

Page 19: ...19 Wiring Diagram ...