4

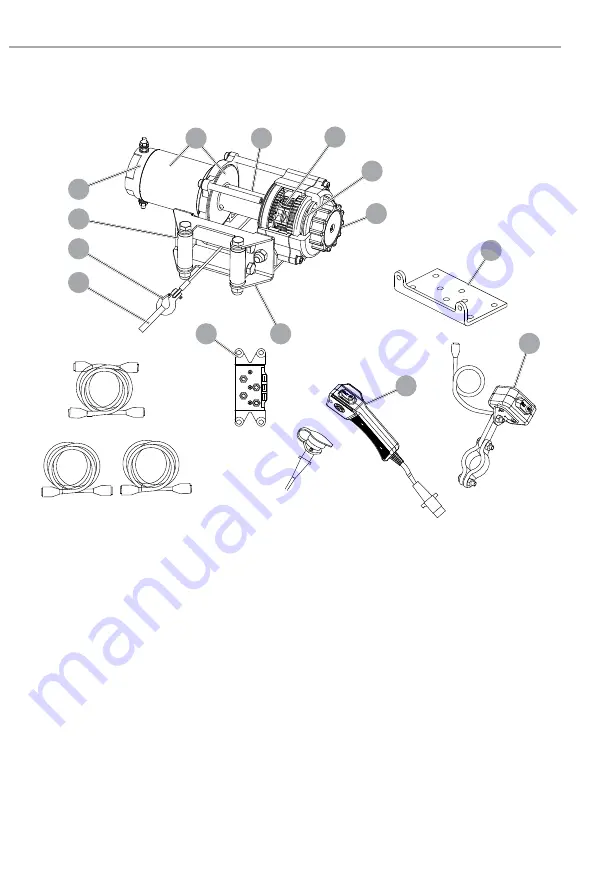

MODEL #A3000 – 3,000LB (1361KG) WINCH

CONTROLS AND fEATURES

ConTrols and feaTures

Read this operator’s manual before operating your winch. Familiarize yourself with the location and function of the

control features. Save this manual for future reference.

1.

Motor

– 1.30 HP 12V DC motor provides power to

the planetary gear mechanism.

2.

Winch Drum

– The winch drum is the cylinder on

which the cable is stored. It can feed or wind the

cable depending on the switch assembly.

3.

Steel Cable

– 3/16 in. x 45.9 ft. Galvanized aircraft

cable designed specifically for load capacity of 3,000

lbs. (44 usable feet with five wraps on the drum).

The cable feeds onto the drum in the “under wind”

position through the roller fairlead (4) and is looped

at the end to accept the clevis hook pin (12).

4.

Roller Fairlead

– When using the winch at an angle

the roller fairlead acts to guide the steel cable onto

the drum and minimize damage to the cable from

abrasion on the winch mount or bumper.

5.

Free Spooling Clutch

– The clutch allows the

operator to manually disengage (“Release”) the

spooling drum from the gear train. Engaging the

clutch (“Engage”) locks the winch into the gear

system.

6.

Braking System

– Braking action is automatically

applied to the winch drum when the winch motor is

stopped or there is a load on the cable.

7.

Planetary Gear System

– The reduction gears

convert the winch motor power into extreme pulling

forces. This system allows high torque while

maintaining compact size and light weight.

8.

Mini Rocker Switch

– Handle bar mounted switch

for powering cable in/out of the winch drum.

9.

Hand Held Remote

– Hand held switch with a

remote socket for powering the cable in or out of

your winch drum.

Winch

1

2

12

3

6

7

6

5

4

11

8

10

13

9