Page 4

Installation Instructions

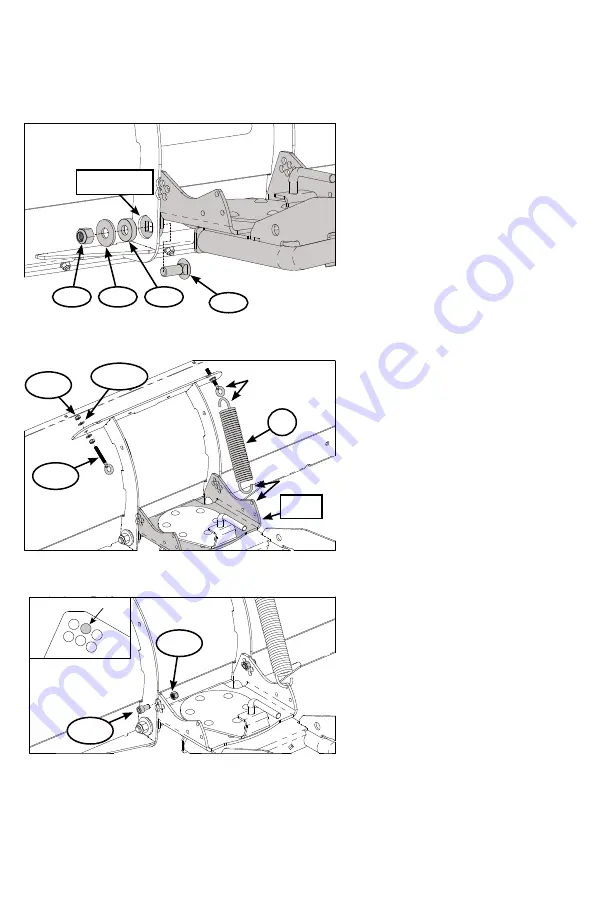

1. To secure the blade to the tube system,

place the pitch bushing (Item 7.4.1) into

the blade gusset hole. Secure the tube

system and the blade together with the

Items 7.3.4 carriage bolt, 7.3.3 washer

and 7.3.2 lock nut, as shown in Figure 1.

Repeat on other side.

2. Insert the plow springs (Item 7.2) into the

top smaller rear holes in the UTV cradle,

as shown in Figure 2. Place the eyebolts

(Item 7.3.8) onto the end of the plow

springs and secure the eyebolts onto the

plow blade gusset, as shown in Figure 2

using Items 7.3.9 and 7.3.10. Leave spring

tension loose as you will decide tension

in Step 5.

3. Assemble on machine and decide desired

pitch of blade. (Blade pitch controls the

angle of which the blade contacts the

ground.) Each hole is 5 degrees of blade

pitch adjustment.

Note: Figure 3 shows the default pitch

position. Recommended for proper blade

level

.

4. With springs installed pitch blade under

tension and install Items 7.3.5 socket head

cap screw and 7.3.1 lock nut into desired

pitch position hole

5. Tighten nuts down on eye bolt until

desired spring tension is reached.

Note: For each 1/4” that the nut is

tightened it will add 8 lbs of spring

tension.

“Figure 1” Pivot Bolt Assembly

BLADE GUSSET

HOLE

7.3.4

7.4.1

7.3.3

7.3.2

“Figure 3” Pitch Adjustment Bolt

(Spring not shown for clarity.)

DEFAULT LOCATION

7.3.1

7.3.5

“Figure 2” Spring Assembly

UTV

CRADLE

7.2

7.3.8

7.3.9

7.3.10