Page 5

6.

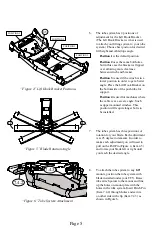

The tube system has 4 positions of

adjustment for the Lift Hook Bracket.

(The Lift Hook Bracket is what is used

to attach your lifting system to your tube

system.) Choose best postion for desired

lift height and cable/rope angle.

Position 1

is the default position

Position 2

uses the same bolt holes,

but in this case the bracket is flipped

over allowing more clearance

between winch and bracket.

Position 3

is used if the winch is in a

lower position in order to get a better

angle. Place the Lift Hook Bracket on

the bottomside of the push tube for

support.

Position 4

is used for machines where

the cable is at a severe angle. Such

as upper mounted winches. This

position will require longer bolts to

be installed.

7.

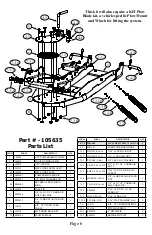

The tube system has three positions of

rotation for your blade. Each adjustment

is at 25 degree increments. In order to

make each adjustment you will need to

pull on the Pull Pin (Figure 4, Item 4.5)

and rotate your blade left or right until

you reach the desired angle.

8.

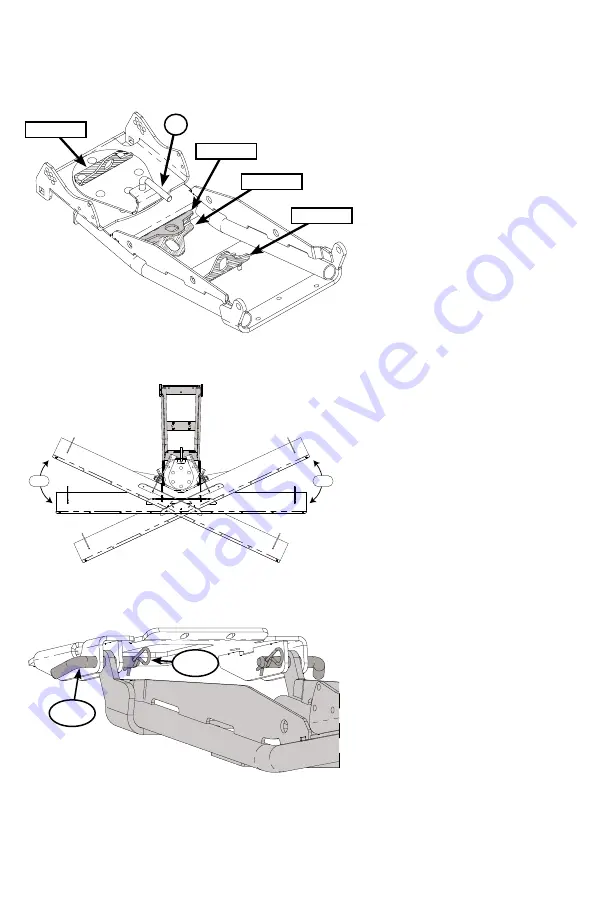

To attach the tube system to any KFI

mounts, position the tube system with

blade installed under your UTV. Raise

tube attach points to the mount and line

up the holes on mount plate with the

holes in the tube system. Insert Hitch Pin

(Item 7.4.2) through holes and secure

on other side with clip (Item 7.4.3) as

shown in Figure 6.

“Figure 4” Lift Hook Bracket Positions

POSITION 4

4.5

POSITION 2

POSITION 3

POSITION 1

“Figure 5” Blade Rotation Angle

25°

25°

“Figure 6” Tube System Attachment

7.4.2

7.4.3