7

MODEL #SE25 – 2,500LB (1134KG) WINCH

ASSEMBLy

22. Connect the battery leads from the contactor to the

vehicle’s battery (black to black, and red to red, see

diagram on page 8).

23. Check for proper drum rotation. Turn the clutch

cap to the RELEASE position. Pull out some cable

from the drum and then turn the clutch cap to the

ENGAGE position to engage the gears. Make sure

your vehicle is running and press the cable out

button on the switch. If the spool is turning and

releasing more cable, then your connections are

accurate. If the spool is turning and collecting more

cable, then reverse the leads on the motor. Repeat

and check rotation.

Wiring the Winch

15. Connect the yellow and blue wires to the motor

terminals on the winch. Torque the nuts on the

motor to 5.7 N-m (50 in lbs) Route the opposite

ends to the contactor location. (See diagram on

page 8).

16. Connect the yellow and blue wires to the contactor

block (yellow to yellow, blue to blue). DO NOT

tighten nuts. (See diagram page 8).

17. Connect the red and black wires to your contactor

block (red to red, black to black). DO NOT tighten

nuts. Route the opposite ends to the battery

location (See diagram page 8).

18. Connect the mini rocker switch to the contactor

block (black to black, green to green). (See diagram

on page 9).

19. Once all wiring is connected to the contactor, finish

mounting it to the contactor location using supplied

M6 hardware (See diagram page 8).

20. Torque the contactor terminal nuts to 4.5 N-m

(40 in lbs) Do NOT over tighten.

21. Place all terminal boots over terminals and secure

all cables with zip ties or electrical tape.

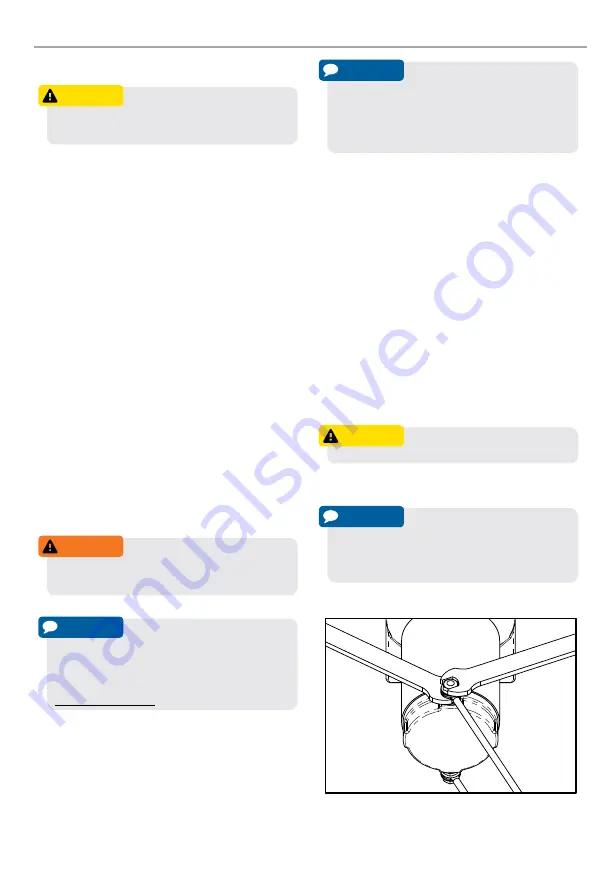

Proper Terminal Tightening

CauTIon

Never route electrical wires across

any sharp edges, through or near moving parts, or

near parts that become hot.

WarnInG

Failure to follow specific wiring

instructions may result in damage to your wiring

system or equipment.

noTICe

Depending on the location of the

contactor, you may need to use an alternate winch

wiring configuration. Please see the “Alternate

Winch Wiring Diagram” available on:

www.kfiproducts.com

noTICe

If you are installing the remote

socket along with the mini rocker switch, you will

need to connect the remote socket to the contactor

and then the mini rocker switch to the remote

socket (see diagram on page 9).

CauTIon

Battery cables should not be drawn

taut. Leave some slack for cable movement.

noTICe

Always hold the bottom nut with

a wrench while tightening motor wire terminals.

Do not allow the bottom nut to spin, else you may

damage the end cap.