Summary of Contents for GT44185A

Page 1: ...151349 03 11 96 KFsW PRINTED IN U S A ...

Page 30: ...REPAIR PARTS TRACTOR MODEL NUMBER GT44185A ELECTRICAL 22 42 41 49 12 28 30 ...

Page 34: ...REPAIR PARTS TRACTOR _ MODEL NUMBER GT44185A DRIVE 57 72 52 1 26 27 34 ...

Page 36: ...REPAIR PARTS TRACTOR MODEl NUMBER GT44185A STEERING ASSEMBLY 36 ...

Page 40: ...REPAIR PARTS TRACTOR MODEL NUMBER GT44185A SEAT 6 17 12 4O ...

Page 42: ...REPAIR PARTS TRACTOR MODEL NUMBER GT44185A MOWER LIFT i 47 14 f 6 13 32 42 ...

Page 44: ...72 77 23 ...

Page 46: ...REPAIR PARTS _TRACTOR _ MODEL NUMBER GT44185A PEERLESS TRANSAXLE MODEL NUMBER 820 0i69 46 ...

Page 49: ...49 ...

Page 50: ...50 ...

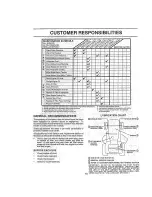

Page 52: ... SUGGESTED GUIDE FORSI L _ ONLYRIDE UPANDDOWN HILL NOT ACROSS RILL r ...