10

RTB SERIES CABLE REEL MANUAL

KH200-02619_REV-A

SECTION 3 - INSTALLATION

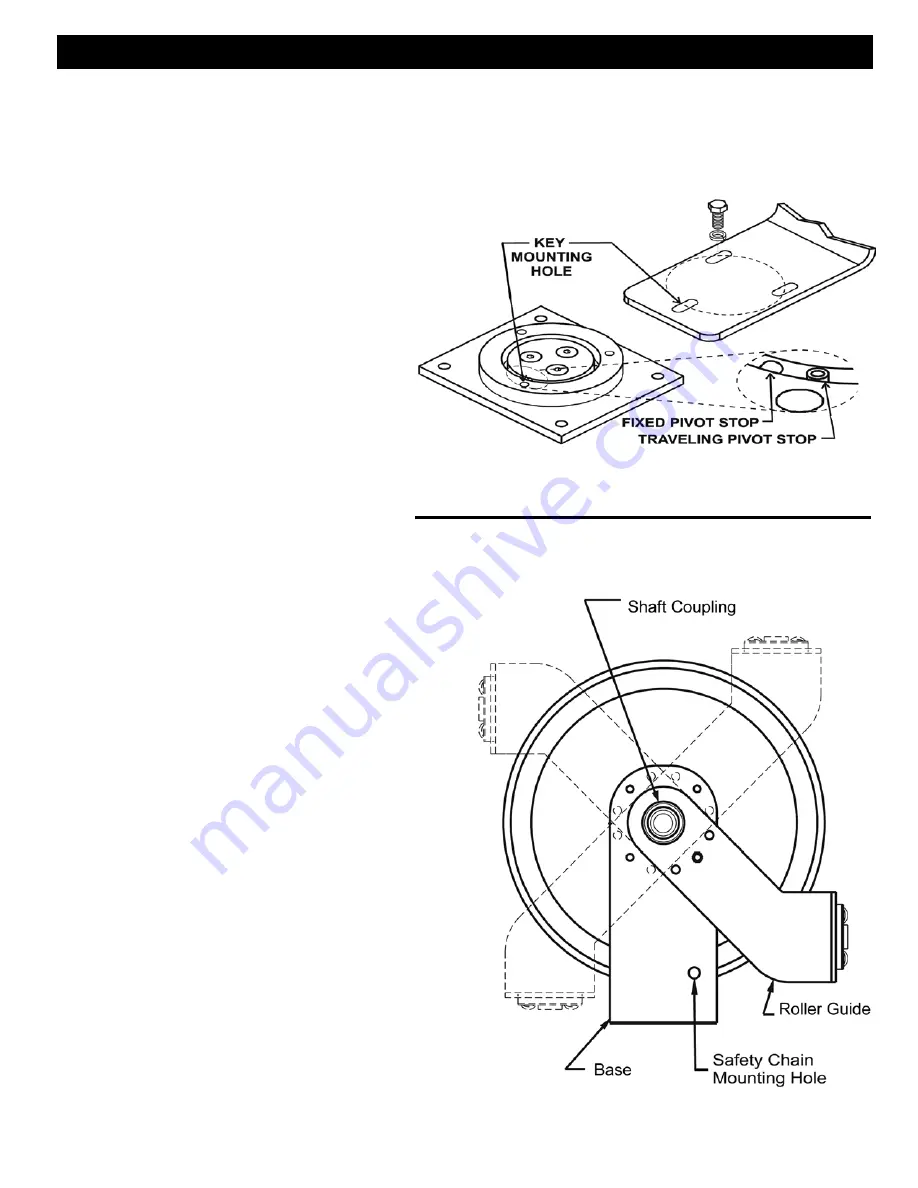

Pivot Base Mounting

(Optional Accessory)

All RTB Series Cord Reels can be furnished with a

pivot base to allow the reel to rotate and keep the

extended cable perpendicular to the application.

See

Figure 10-1

.

The PVB Pivot Base will rotate up to 345°. Travel

can be limited to 90°, 180°, or 270° by installing

an additional roll pin in the appropriate available

hole.

A pivot base is required for carousel or loop track

applications.

When a pivot base is used the reel must be

mounted horizontally (“ceiling” or “floor”

mounted).

The roller guide should be mounted to require

the cable to travel perpendicular to the axis of

rotation. This will guard against cable twisting and

ensure effective swivel action from the pivot base.

Swing mount and swivel base available, consult

factory.

Roller Guides

All RTB Series units are equipped with a roller

guide. The guide’s function is to center the cable

on the spool and to help the reel wrap cable more

evenly. See

Figure 10-2

.

The cable should not bear against either end of

the spool during winding as this will tend to inhibit

level winding of the cable.

The guide should be secured at the best of twelve

possible positions so that a minimum change of

direction occurs at the guide; otherwise, cable life

will be reduced.

A max 15° angle from guide arm center to cable

pay out from reel is suggested.

The guide arm is shipped attached to the reel. The

guide must be located and secured in the most

appropriate position with the 5/16-18 x 5/8” hex

head screw and lock washer provided, prior to

making any electrical connections.

Figure 10-2

Figure 10-1