16

RTB SERIES CABLE REEL MANUAL

KH200-02619_REV-A

SECTION 5 - MAINTENANCE

BE SURE THE POWER IS OFF FOR ALL MAINTENANCE.

Lubrication

•

All springs and bearings are lubricated for life at the factory. Additional lubrication should not be required.

•

Do not apply any lubricants or solvent cleaning agents to slip ring, brush or insulator surfaces.

Inspections

•

Periodically check the reel for any loose or missing fasteners. Tighten or replace as necessary.

NOTE

•

Do not over tighten, this will cause fasteners to snap.

•

The slip ring assembly should be checked periodically as follows:

»

Clean to remove dust and dirt from the slip ring housing area and all slip ring assembly and brush surfaces.

»

Inspect cable for damage or wear which would make it unsafe to use.

Slip Ring & Feed Cord Replacement

The slip ring assembly should be replaced, not rebuilt, if it becomes damaged.

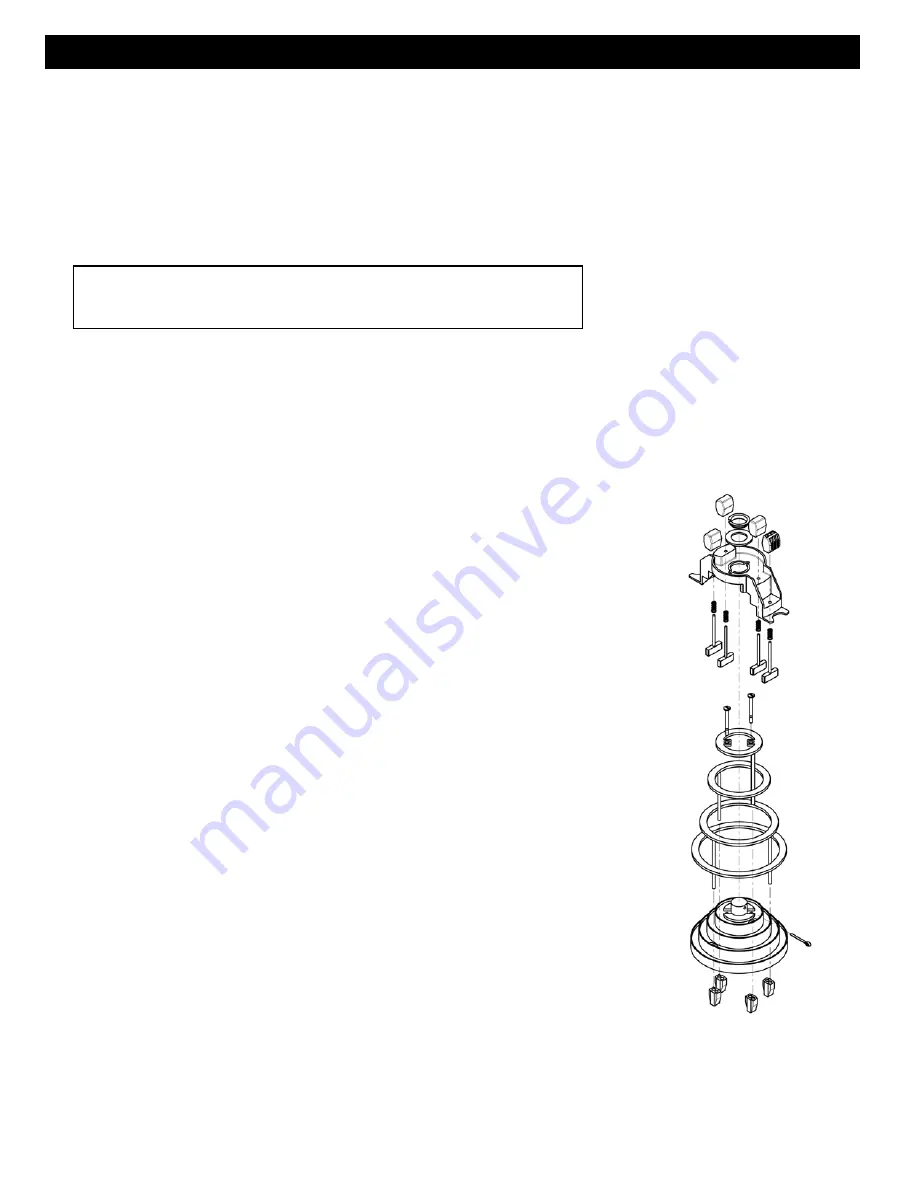

1. Remove the 4 screws securing the outer flange. Remove outer flange and

gasket from remaining assembly. Remove or unwrap the cable from the

drum and lay it next to the reel. See

Figure 16-1.

2. Disconnect the wires from the spool cable. Remove the drum (black

plastic tube) from the reel and place next to the slip ring.

3. Loosen feed cord watertight located at the shaft end.

4. Remove the brush block from the slip ring by removing the cotter pin and

washer at the top of the slip ring assembly. Remove the 2 screws securing

the slip ring to the shaft. See

Figure 16-1

.

5. Remove the slip ring from the shaft while feeding in the feed cord

through the shaft. Cut wires if they are butt spliced or disconnect

connectors if locking wire connectors are used. Reinsert the washer

and cotter pin after removal of the slip ring from the shaft to keep the

assembly together.

6. Carefully and thoroughly clean the inside surfaces of both flanges and

the drum. Inspect both gaskets for damage and replace as necessary.

Caution

: Damaged gaskets may affect UL / CSA rating of reel.

7. Remove old feed cord and insert approximately 5” -10” of new feeder

cord through the watertight and shaft. Secure cable-tie as shown in

Figure 13-2

(page 13).

8. Install inner gasket.

9. Connect the slip ring leads to the feed cord with the provided wire

connectors and install the slip ring on the shaft. Ensure the wire

connectors are outside the shaft and under the slip ring body before

securing the slip ring to the shaft. Be careful not to over tighten or strip

the Phillips head screws.

10. Install the 2 screws to secure the slip ring to the shaft.

11. For remaining assembly, follow Cable Installation and Spring Tension

Adjustment in Section 3.

Figure 16-1