11

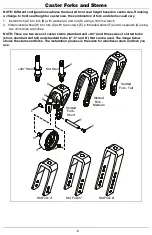

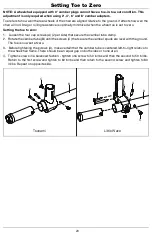

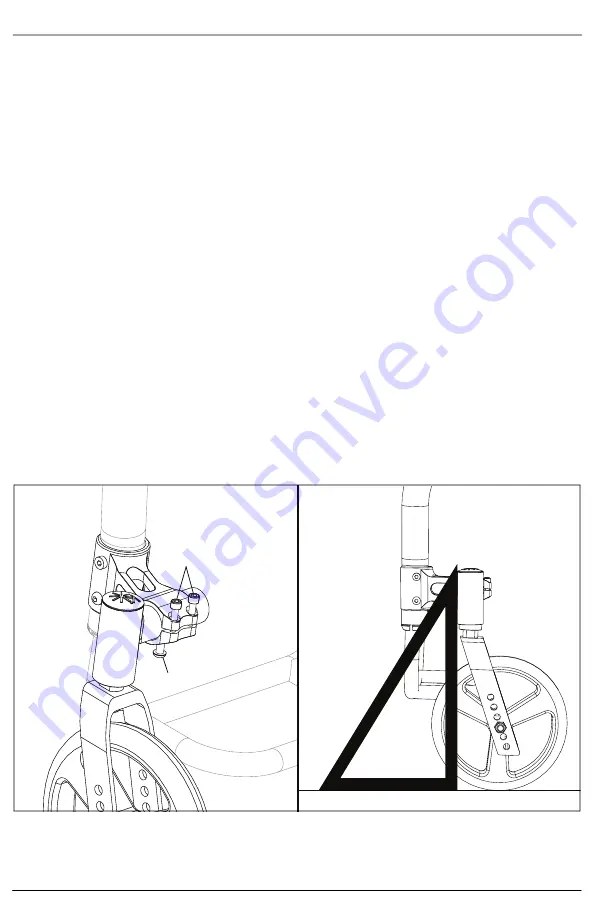

Caster Angle and Squaring

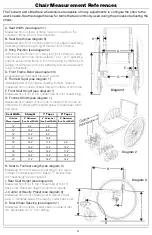

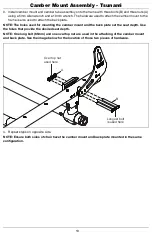

To maintain optimal performance of your Tsunami and Little Wave, the front caster housing should always

be aligned perpendicular to the ground. Your chair is shipped aligned. It is recommended that caster

squareness is checked after making adjustments to the chair configuration related to any of the following

items: caster size or type, camber, rear wheel, tire, center of gravity and seat heights. Caster squareness

should always be the last check made prior to use after adjustments or changes to the chair have been

made.

After all other adjustments are made you should check your caster housing alignment and realign if the

housing is not perpendicular to the ground.

NOTE: A hole has been drilled in the caster housing to ensure squareness. This hole helps keep the

caster square, but it does allow adjustment of up to 4° in the case that the caster needs to be

resquared. See instructions below.

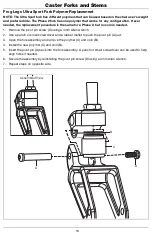

Adjusting the Caster Angle:

For optimum performance, the caster housing should always be at 90° angle to the floor (perpendicular to

the ground).

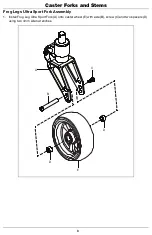

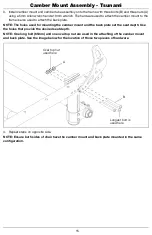

1. To change the angle, place the chair on a flat surface (such as a table).

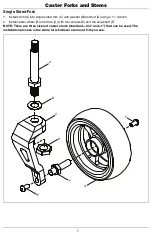

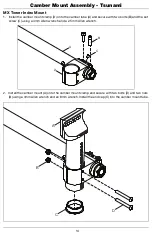

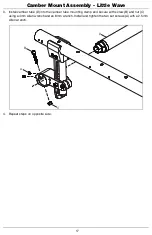

2. Loosen the two 5mm Allen screws on the top of the caster housing clamp. This will allow the caster

pivot tube to rotate freely (A).

3. Loosen the one screw (B) underneath the housing clamp using a 4mm Allen wrench.

4. Place a large right triangle against the table surface and the front surface of the caster bearing housing.

This will align the caster stem rotational axis perpendicular to the floor surface.

5. When the alignment is correct, retighten the two 5mm retaining screws to 80 in/lbs.

6. Tighten screws in a balanced fashion - tighten one screw to 50 in/lbs and then the second to 50 in/lbs.

Return to the first screw and tighten to 80 in/lbs and then tighten last screw to 80 in/lbs. Repeat on

opposite side.

7. Retighten the one screw underneath the housing clamp using a 4mm Allen wrench.

A

B