8. Operation

1.

13

When the engine tends to stop frequently at idling

mode, turn the adjusting screw clockwise.

When the cutting head keeps rotating after releasing

the trigger, turn the adjusting screw counter-

clockwise.

2.

ADJUSTING THE THROTTLE CABLE

(1) Cable adjuster

ADJUSTING THE IDLING SPEED

(1) Idle adjusting screw

NOTE

1 ~ 2 mm

The normal play is 1-2mm when measured at the

carburetor end. Readjust with the cable adjuster if

required.

Warm up the engine before adjusting the idle speed.

STRIMMER / BRUSH CUTTER

WARNING

1.

2.

Always wear eye protection such as safety gog-

gles. Never lean over the rotating cutting head.

Rocks or other debris could be thrown into eyes

or face and may cause serius personal injury.

Keep the cutting attachment guard in place at all

times when the unit is operated.

TRIMMING GRASS AND WEEDS

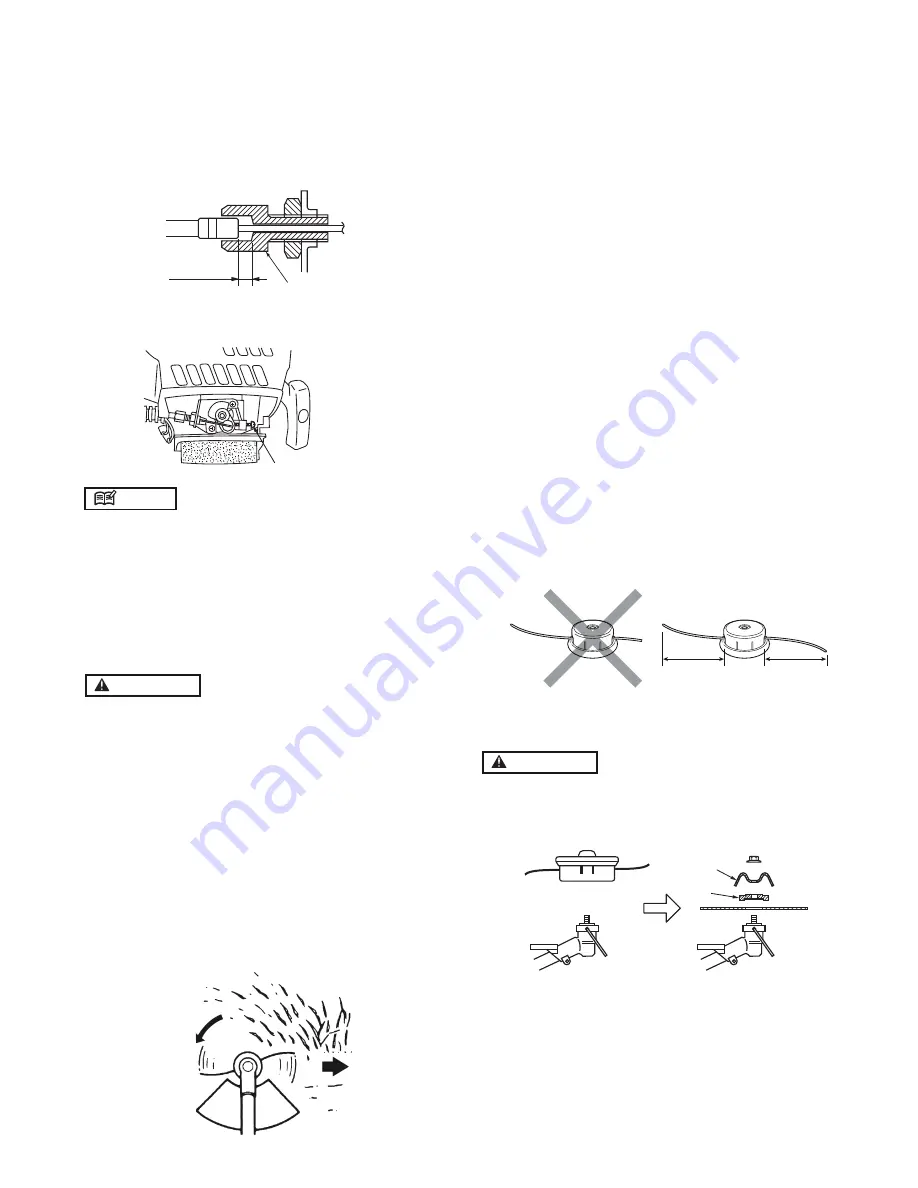

• Always remember that the TIP of the line does cut-

ting. You will achieve better results by not crowding

the line into the cutting area. Allow the unit to trim at

its own pace.

1. Hold the unit so the head is off the ground and is tilted

about 20 degrees toward the sweep direction.

2.

3.

4.

5.

6.

You can avoid thrown debris by sweeping from your

left to the right.

Use a slow movements to cut heavy growth. The

rate of the cutting motion will depend on the material

being cut. Heavy growth will require slower move-

ments than light growth.

Never swing the unit quickly/roughly as you will be in

danger of losing your balance or control of the

machine.

Try to control the cutting motion from the hip rather

than placing the full workload on the arm or hands.

Take precautions to avoid wire, grass or weeds from

wrapping around the head shaft. Such materials

can stall the head and cause the clutch to slip result-

ing in damage to the clutch system.

ADJUSTING THE LINE LENGTH

•

•

Your strimmer is equipped with a semi-auto type

nylone line head that allows the operator to increase

the line length without stopping the engine. When

the line becomes short, lightly tap the head on the

ground while running the engine on full throttle.

Each time the head is bumped, the line increases

about 1 inch (25.4mm). For better effect, tap the

head on clear ground or hard soil. Avoid bumping in

thick growth.

WARNING

(1)

(2)

(1) Cover: 3540-13283

(2) Holder: 6019-13250 (Attachment)

1. Detach the line head assembly completely.

2. Put on the blade, making the marked side face the

holder, put on the outer holders, and fasten the blade

with the blade nut.

When sharpening, removing or attaching the blade,

be sure to wear thick sturdy gloves and use only

proper tools and equipment to prevent injury.

SETTING UP BRUSH CUTTER BLADE