9. Maintenance

IMPORTANT

(1) Cylinder

(2) Intake air cooling vent (back)

PROCEDURES TO BE PERFORMED AFTER

EVERY 100 HOURS OF USE

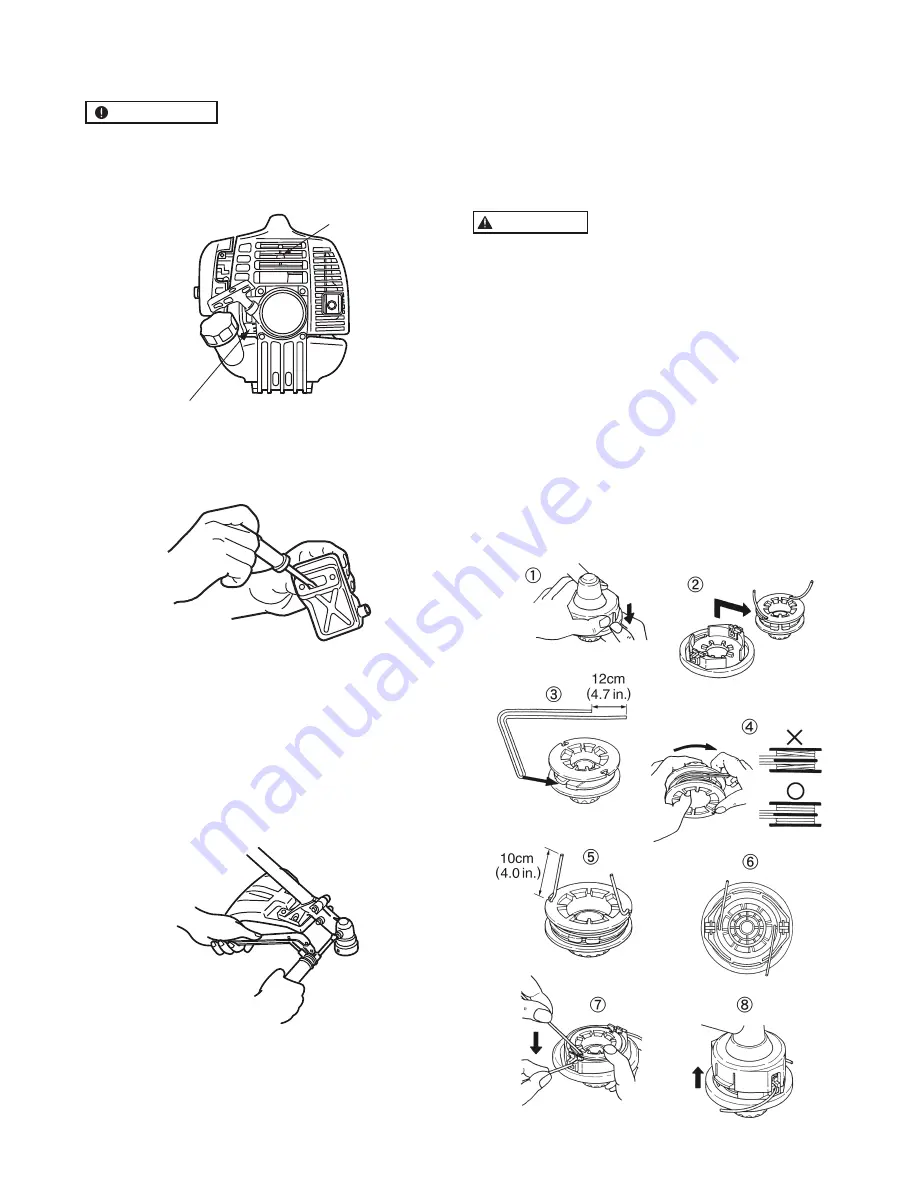

REFILLING STRIMMING LINE

1. For replacement line, use a diameter of 2.4mm(.095in).

The spool is capable for a line upto 6m(20ft) on the

10cm(4”) head. Avoid using a larger line as it may cut

down the trimming performance.

WARNING

For safety reasons, do not use metal reinforced line.

2. Pinch the slotted area on the both sides of the spool

housing to unhook the bottom cap.

3. Take out the spool and pull off the old line. Put one

end of new line through the spool holes and pull it

until the length is equal between each part of the line.

4. Wind up the line in the correct direction as indicated

on the spool.

5. Hook each end of the line in the slot on the edge of

the spool, and then put the ends through the eyelets

on the housing. Make sure that the spring and the

washers are in place.

6. While holding the spool against the housing, pull the

line ends to release them from the slot.

7. Line up the slot on the bottom cap with the hook on

the housing, press the cap against the housing until it

clicks.

17

If waste gets stuck and causes blockage around the

intake air cooling vent or between the cylinder fins,

it may cause the engine to overheat which in turn

can cause mechanical failure.

1.

2.

Remove the exhaust, insert a screwdriver into the

vent and wipe away any carbon buildup. Wipe away

any carbon buildup on the exhaust vent and cylinder

exhaust port.

Tighten all screws, bolts and fittings.

Check to see if any oil or grease has worked its way

in between the clutch lining and drum, if it has wipe

it away.

3.

ANGLE TRANSMISSION

•

The reduction gears are lubricated by multipurpose,

lithium-based grease in the angle transmission. Sup-

ply new grease every 25 hours of use or more often

depending on the job condition.

•

Remove the cutter holders before installing new

grease to arrange for old grease to exit.