6. Setup

Insert the cable

to the end of

adjuster

Full on stopper

Idling adjust screw

M3 screw

Adjuster

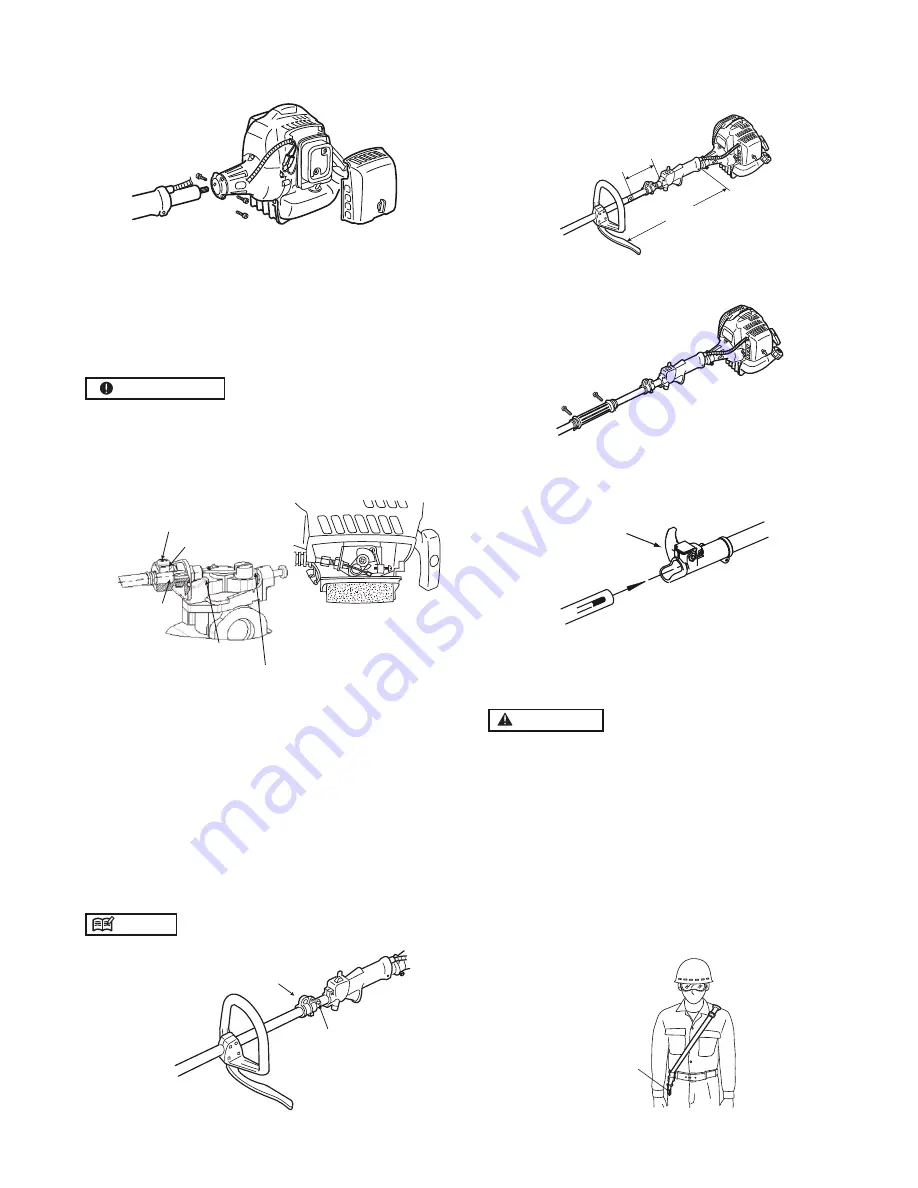

MOUNTING ENGINE

1.

2.

3.

IMPORTANT

Tighten the screws gradually.

CONNECTING THROTTLE WIRE

1. Remove the air filter cover.

2. Connect the end of the throttle wire to the joint on the

top of the carburetor.

3. Connect throttle wire with carburetor. Insert the cable

to the end of adjuster fix the throttle cable by tighten-

ing M3 screw. (Tightening torque: 0.4 ~ 0.8 N.m.)

4. Make sure the ‘STOPPER-PLATE’ of carburetor moves

to contact with ‘IDLING ADJUST SCREW’ and the

‘SWING-ARM’ of carburetor moves to contact with

‘FULL ON STOPPER’ by gripping throttle lever.

CONNECTING SWITCH WIRES

• Connect the switch wires between the engine and the

main unit. Pair the wires of the same colour.

SUSPENSION POINT

NOTE

Shoulder harness goes on this point

•

Mount the handle to the shaft tube and suspension point

at a location that is comfortable for you.

•

MIN

SPA

CING

About 19 inches (48 cm)

INSTALLING HANDLE

arrow mark

SUSPENSION POINT

8

JOINT ATTACHMENT

•

Insert the attachment to the main shaft.

•

Tighten the knob bolt securely

.

Knob bolt

Push the shaft tube towards the clutch housing and

rotate the drive by hand to check that it is engaged

with the gears.

Insert the shaft tube into the clutch housing and align

the positioning hole on the clutch housing and the

shaft tube. Install the screw.

Fasten the clamp securely with two screws.

Install the shaft grip to the shaft tube and clamp

down at a position most suitable for you.

HARNESS

WARNING

ALWAYS WEAR THE PROVIDED HARNESS WHEN

USING THE MACHINE!

Always make sure the machine is hooked

securely to the harness. If you don’t, you will not

be able to control the machine safely. This may

result in injury to yourself and/or others. Never

use a harness with a defective quick release or

any other damage.

HOW TO WEAR HARNESS

1.

(1) Hanger

Wear the provided harness with the hanger on

your right side.