8. Maintenance

Every Every Every

25

50

100

System/components

Procedure

Before

hours hours hours Note

use

after after after

fuel leaks, fuel spillage

wipe out

fuel tank, air filte

r

, fuel filter

inspect/clean

replace, if necessary

r

o

t

e

r

u

b

r

a

c

e

c

a

l

p

e

r

g

n

it

s

u

j

d

a

e

e

s

idle adjusting screw

r

a

s

s

e

c

e

n

f

i

d

e

e

p

s

g

n

il

d

i

y

m

m

7

.

0

~

6

.

0

:

P

A

G

t

s

u

j

d

a

e

r

d

n

a

n

a

e

l

c

spark plug

r

p

a

g

g

u

l

p

eplace, if necessary

intake air cooling vent

clean

throttle trigger, stop switch

check operation

clean

take it to a service dealer

cutting parts

if something is wrong

gear case

grease

screws/nuts/bolts

tighten/replace

not adjusting screws

plate receive

make sure to attach

E

NI

G

NE

RE

M

MI

RT

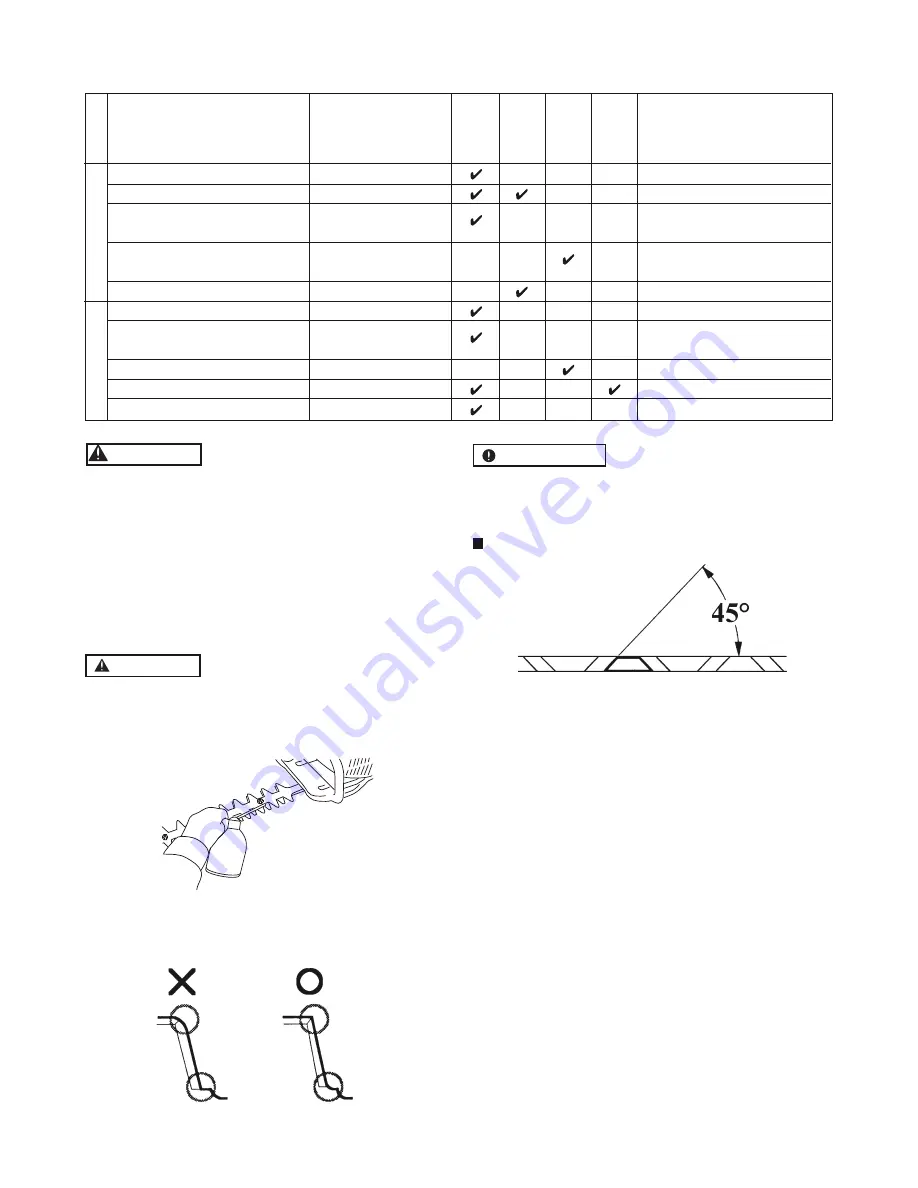

WARNING

•

Make sure that the engine has stopped and is cool

before performing any service to the machine. Con-

tact with moving cutting head or hot muffler may

result in a personal injury.

BLADE

•

Clean any resin and plant reside from the blade be-

fore and after using the machine.

•

Check the cutting edges and refor

m with a flat file.

WARNING

• Make sure that the blade bolts are well tightened.

• The blade assembly is designed to automatically

compensate for any play between the blades.

Point :

1. Keep the end corner sharp.

2. Round the root of the edge.

3. Do not use water when using a grinder.

IMPORTANT

When mounting the blade, make sure to fasten the

spacer, washer and bolt, then fasten the nut.

SHARPENING

Always keep the

file

or sharpener at an angle of 45° to

the blade, and:

•

Always grind in the direction of the cutting edge;

•

Note:

files

cut only in one direction; lift the

file

from

the blade when returning to start a new pass;

•

Remove all burr from the edge of the blade with a slip

stone;

•

Remove as little material as possible;

•

Before r

efitting

the sharpened blades, remove

filing

s

and then apply grease.

Do not try to sharpen a damaged blade, replace it.

10